MkaPEB Cost-Reduction Strategies

In today’s market, competition is getting tougher every day. But steel structure manufacturers and engineers are up for the challenge! They’re looking for ways to create projects with high quality standards in the most economical way.

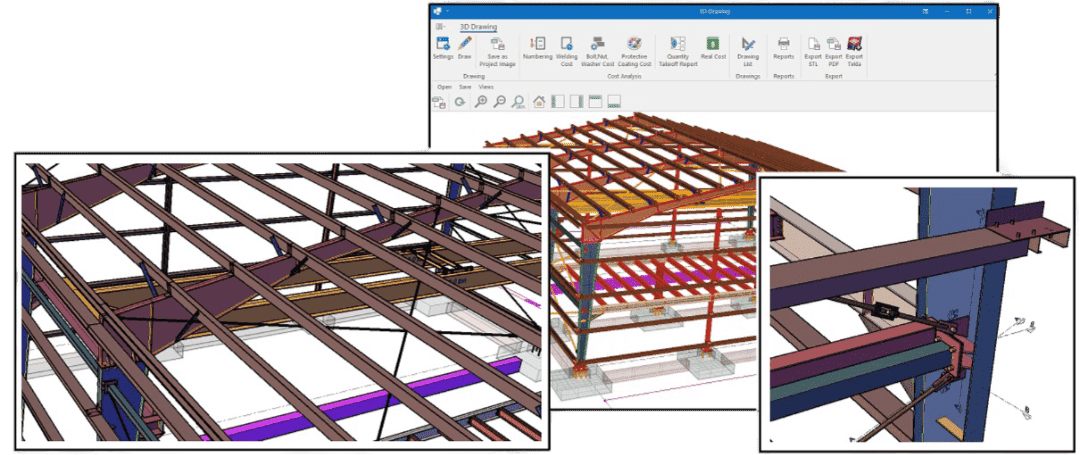

In the following sections, you’ll see what we do with MkaPEB to achieve this goal.

The relationship between the cost of a building and its type.

The economics of a steel structure are dependent on the quantity of materials used and the required labour time.

The amount of steel material, availability of material and unit price all affect the economy. The production habits and machinery of the manufacturing factory have a significant impact on labour time. Production time is another factor that bidding manufacturers consider.

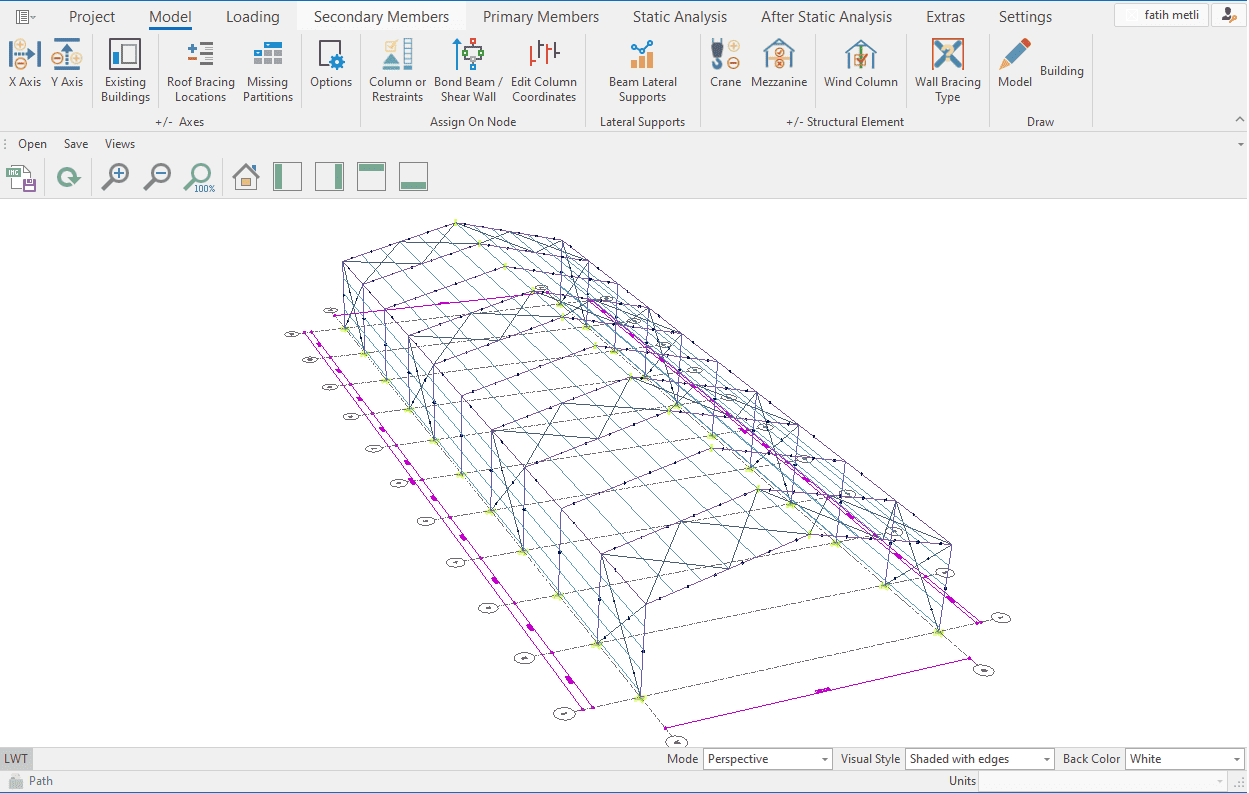

When we think of single steel structures, we think of pre-engineered, portal frame and steel truss structures. Which of these is the most economical is limited by the possibilities and capabilities. In the following chapters, we will see when and which is the most economical.

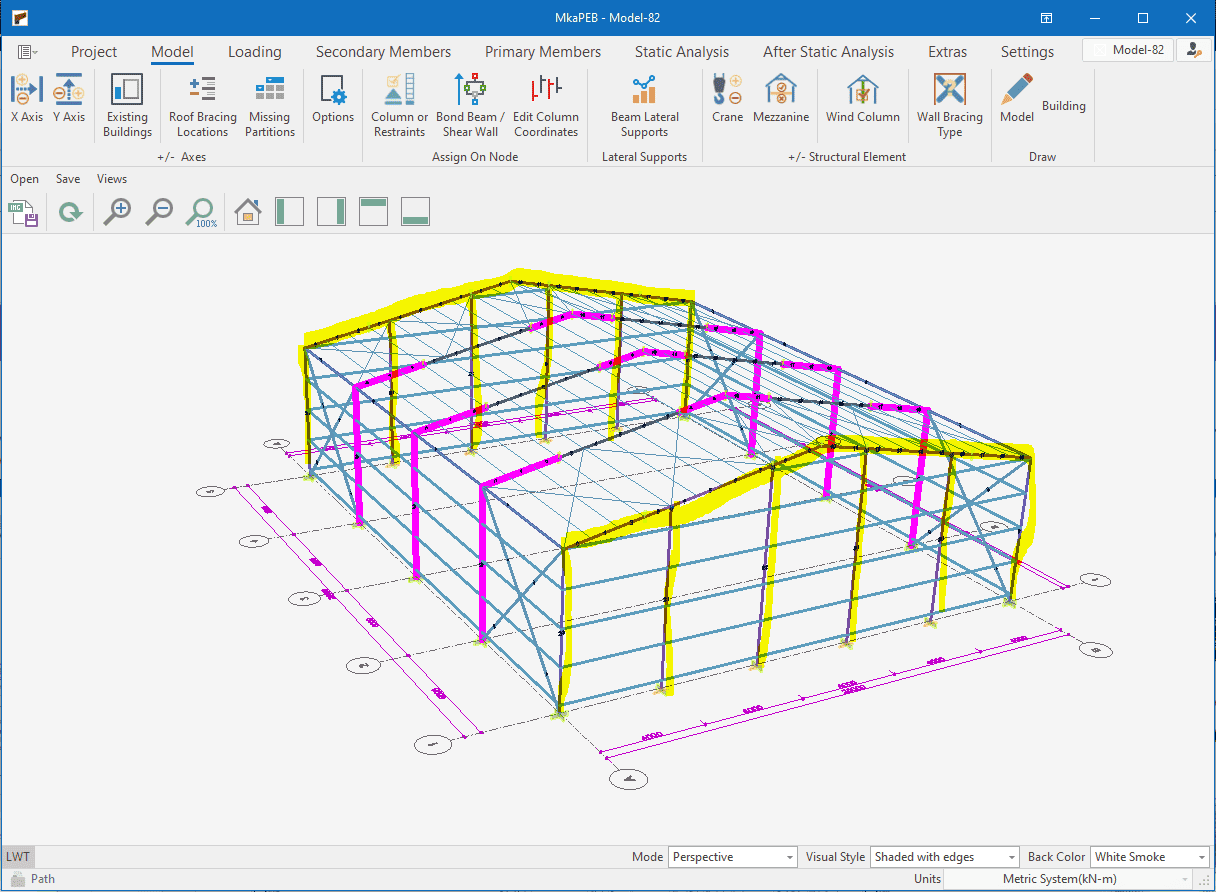

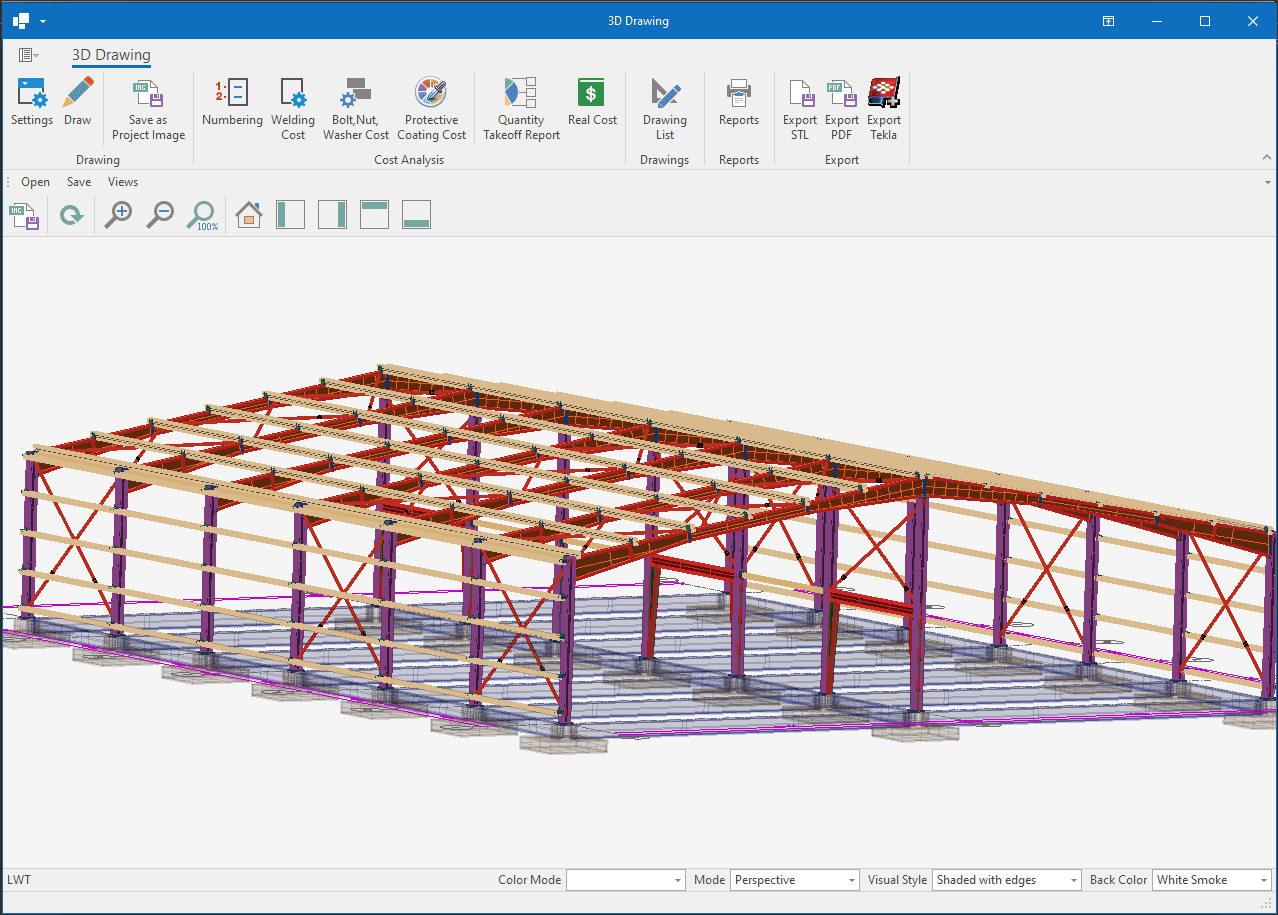

A- PRE-ENGINEERED BUILDINGS

PEB type structures are the most economical steel structures. However, special lines must be installed in the factory for such structures. They are especially preferred in regions where competition is intense, hot-rolled profiles are expensive and access is difficult. Software that cannot project PEB type structures has no chance in these markets. MkaPEB is the one with the most comprehensive features of the three software developed specifically for PEB type structures.

Machine Park Effect

1- Plate cutting process

PEB type structures are the most economical solution for single-storey steel structures. Columns and beams with variable cross-sections are the key to achieving economic results in PEB type structures. However, there is a lot of welding involved in these structural elements with variable cross-sections. This line allows you to make these welds in the desired quality and quickly.

2- Automatic submerged arc welding line

In PEB type structures, the cutting speed of steel plates has a significant impact on the total manufacturing time. The use of multi-head CNC plasma to cut upper and lower flanges of columns and beams is the most effective way to increase speed.

3- H beam straightening machine

In PEB type structures, the web thickness of build-up columns and beams is generally quite thin. After the welds between the flange and the web plates, rotations occur in the beam web. These rotations must be straightened.

B- PORTAL FRAME BUILDINGS

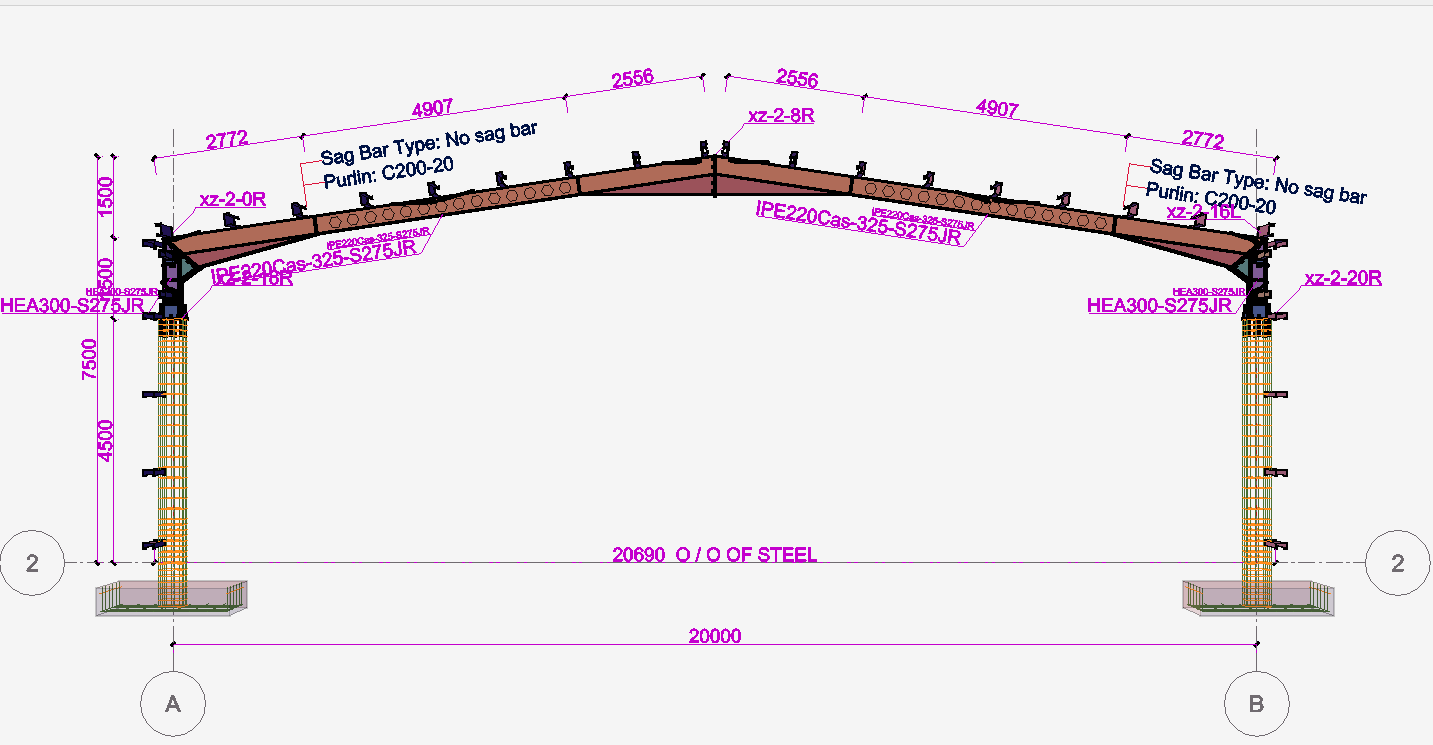

Portal frames are the preferred choice in regions where material supply is not an issue and labour costs are high. They are used in relatively small structures, unlike the PEB type, which is not suited to such small buildings. Many owners of these buildings have limited time, so they often turn to smaller manufacturers who can produce this type of steel structure quickly and efficiently. This is a common practice for the reasons I have already outlined. MkaPEB is the best option compared to its counterparts in this type of structure thanks to its numerous features.

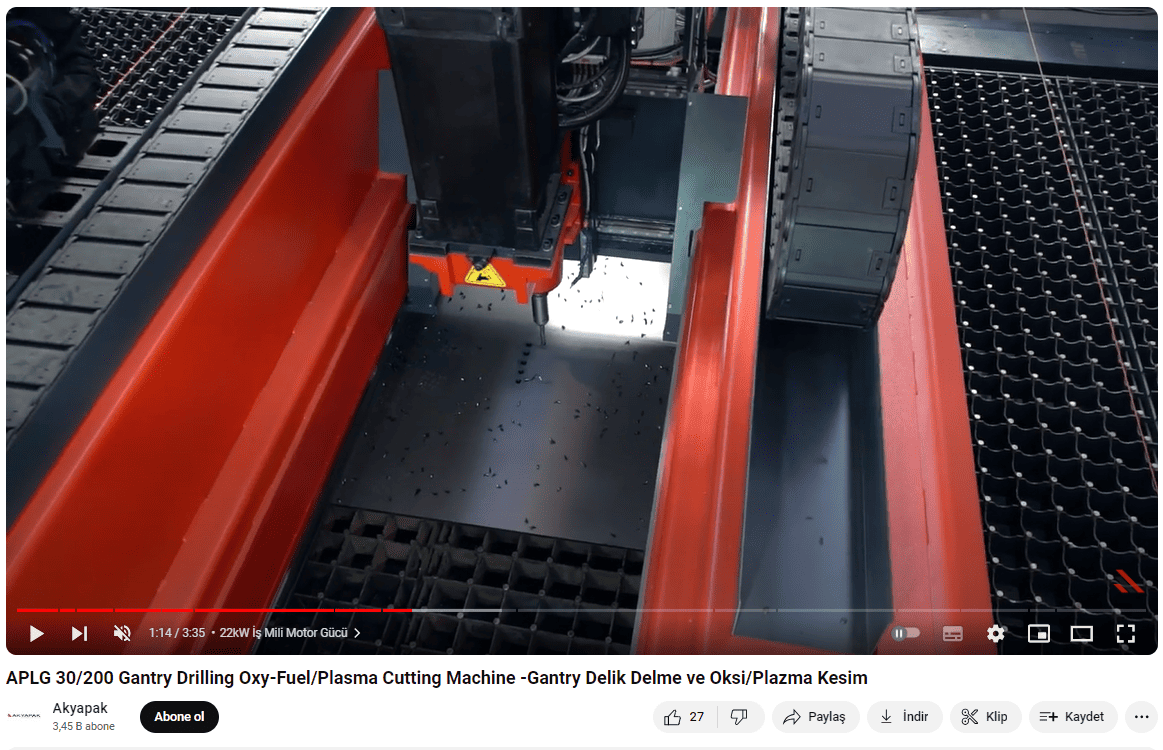

1- Plate thermal cutting and drilling process

Quality management systems such as EN-1090-2 and AISC-207 are in place for steel structure manufacturing. Holes must be drilled in steel plates without being subjected to heat treatment. This means that oxy-fuel or plasma drilling is not an option. There are two ways to proceed:

a. Cut the sheets with plasma, then open the holes with a hole punching machine.

b. Use a machine that drills holes with a vertical drill and cuts the sheets with oxy-fuel or plasma.

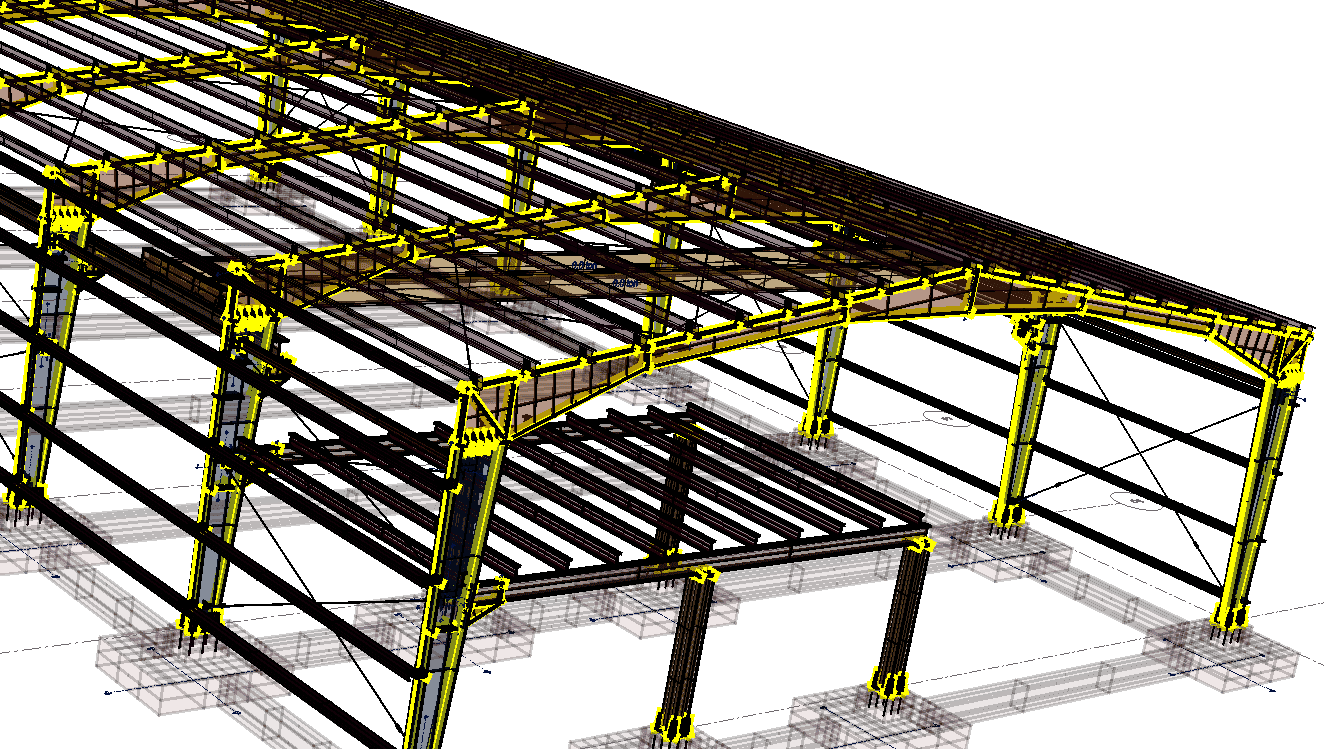

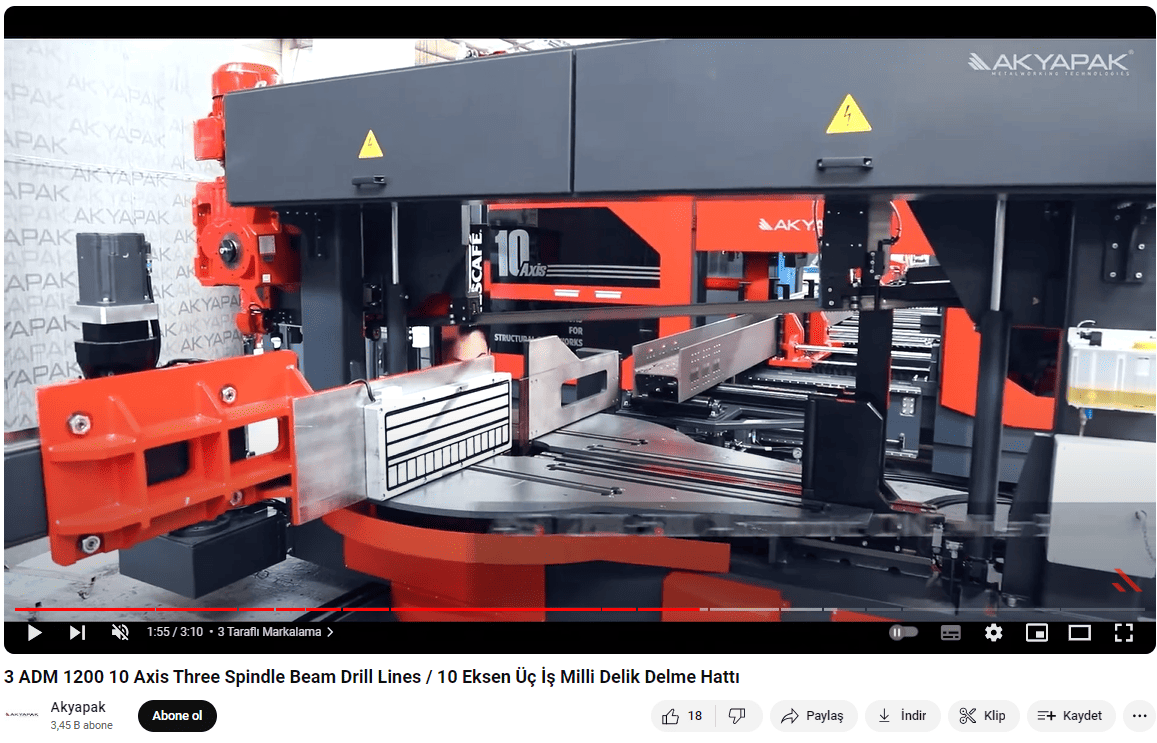

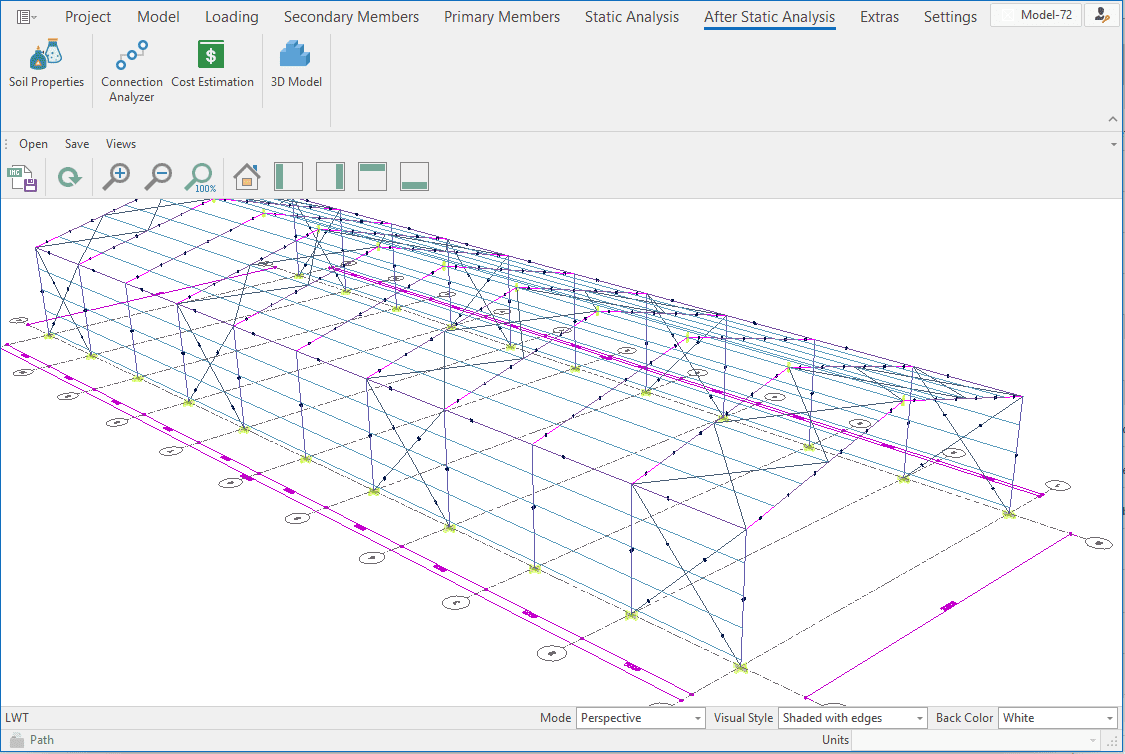

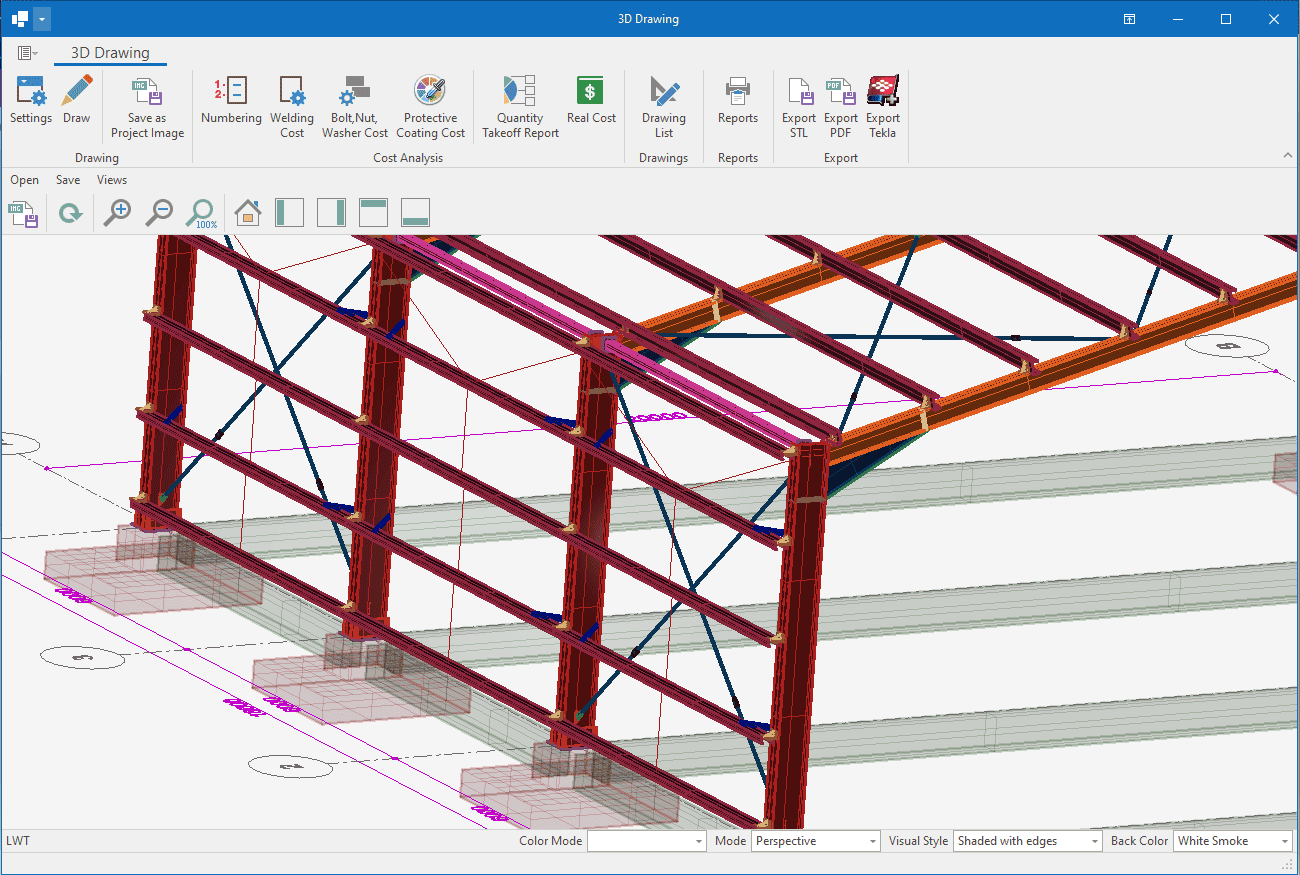

2- Steel profile cutting and drilling process

Nowadays, many CNC machines can drill and cut steel profiles using DSDV-NC files. MkaPEB is the solution for companies with such machines, producing NC files that ensure the structure seen in the 3D model is produced error-free with CNC machines.

3- Castellated Beam (Honeycomb) process

Castellated beams have been used for many years and provide economical results. If the manufacturer has the necessary equipment to make honeycomb beams, it provides a competitive advantage. However, when outsourced to a subcontractor, the economy it provides should be evaluated in terms of weight and unit price.

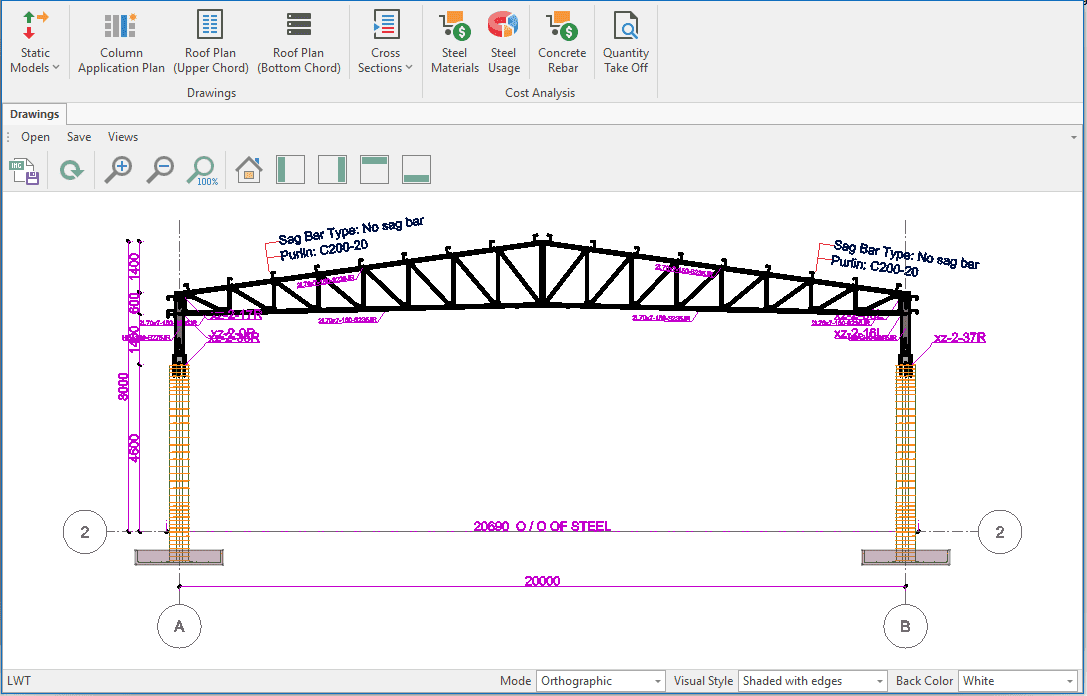

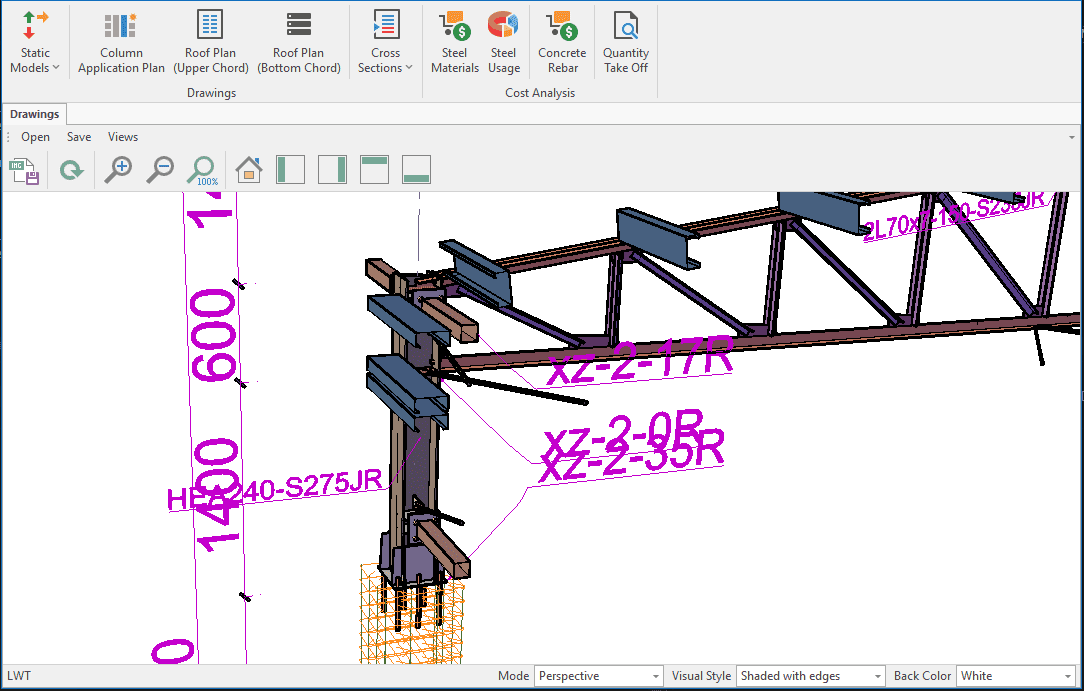

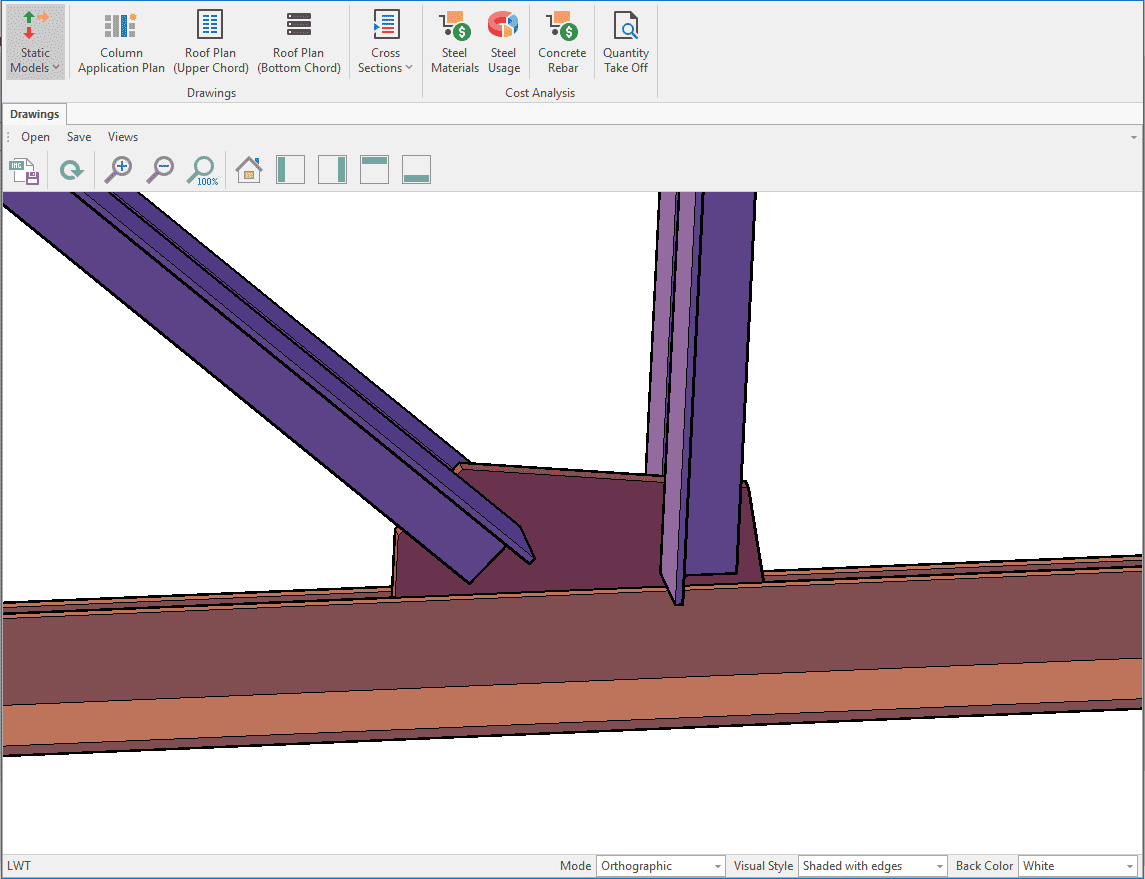

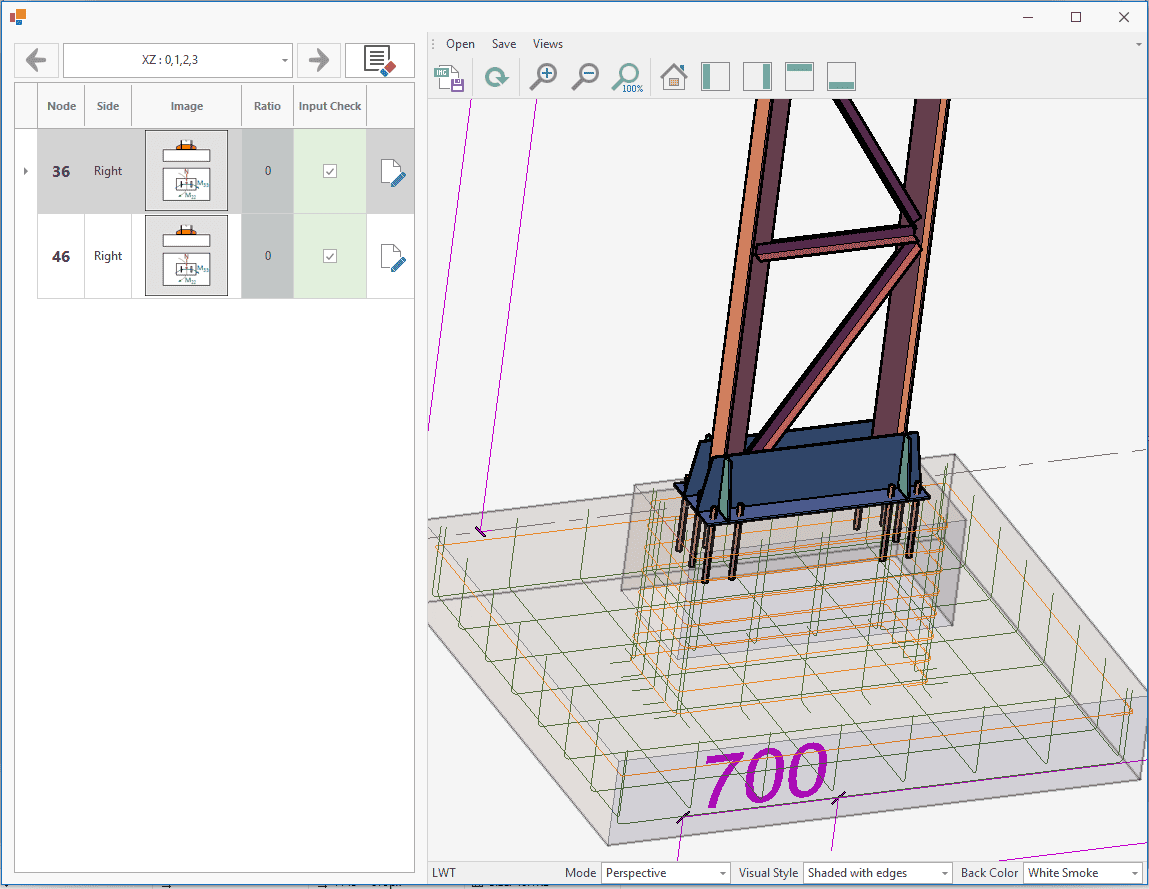

4- Portal frame with reinforced concrete columns

New actors are joining the steel structure manufacturing market every day. They want to get one step ahead of the competition with quality, cheap and timely manufacturing methods. Reinforcing the columns of the portal frame type structure up to a certain level is one of the most popular methods of recent times. MkaPEB provides you with tried and tested methods.

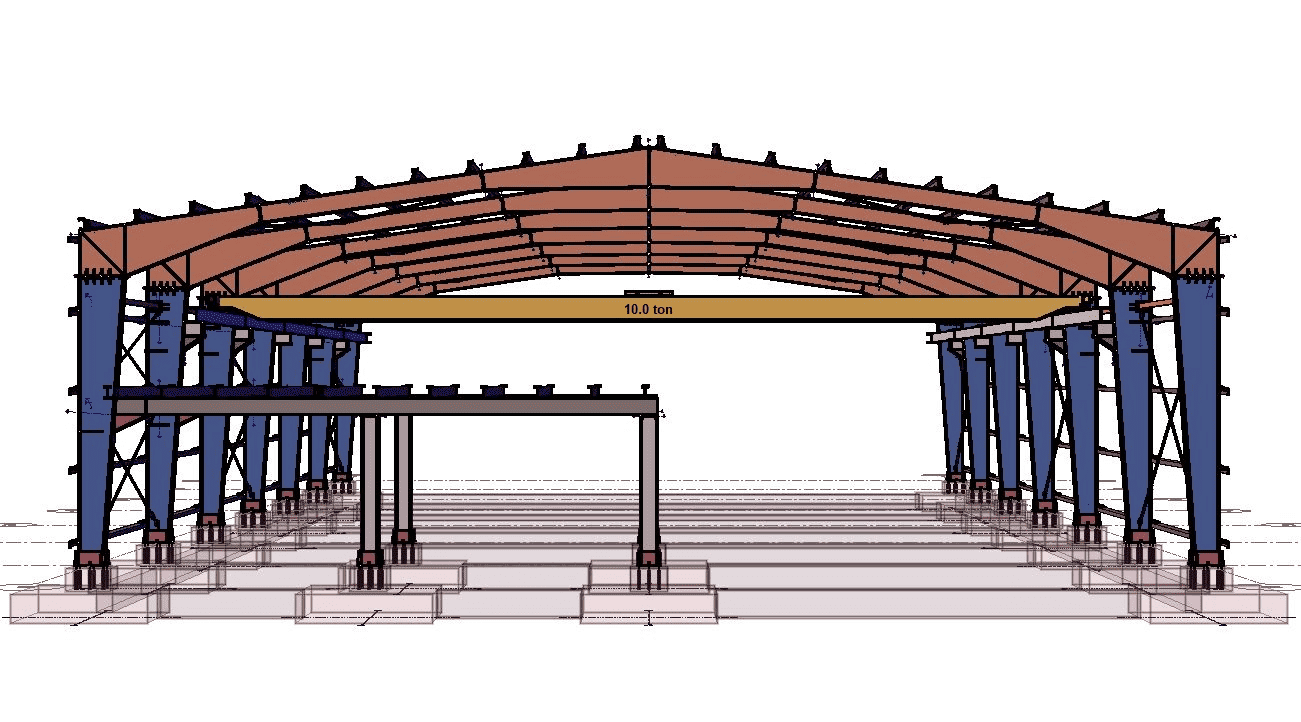

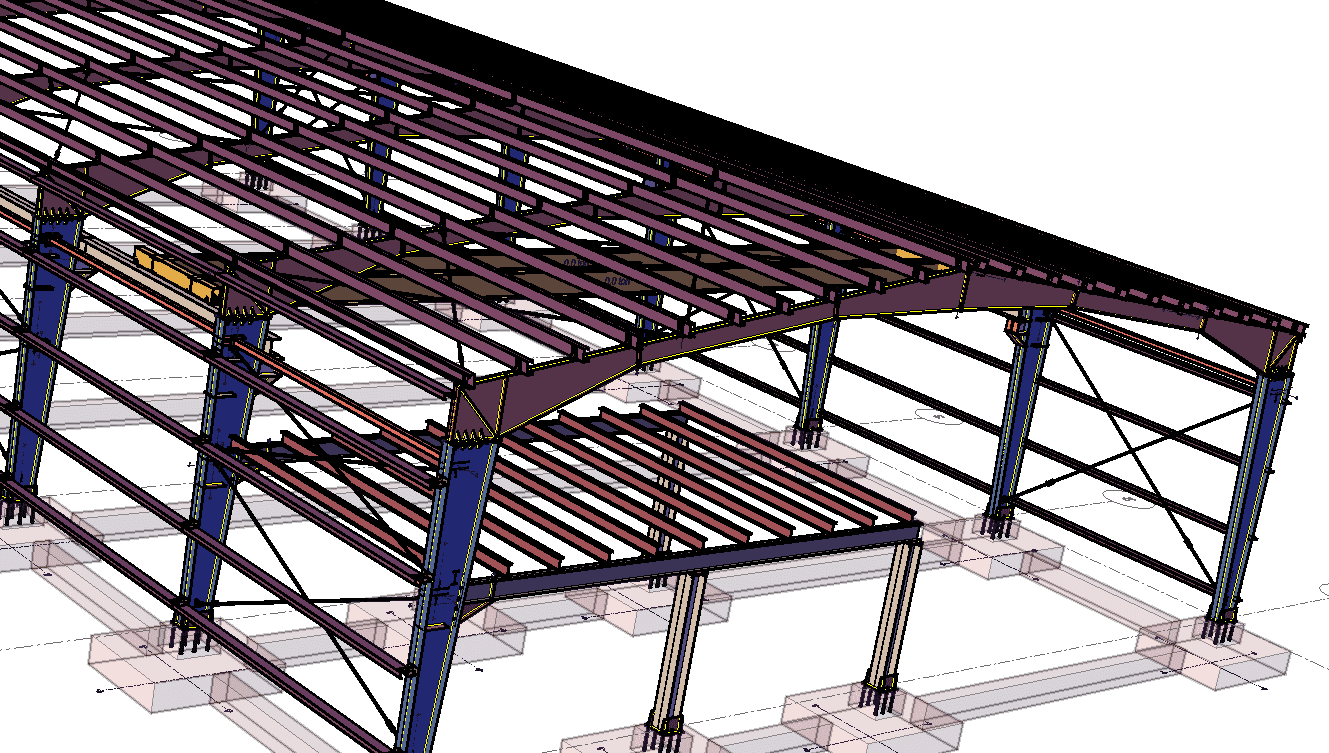

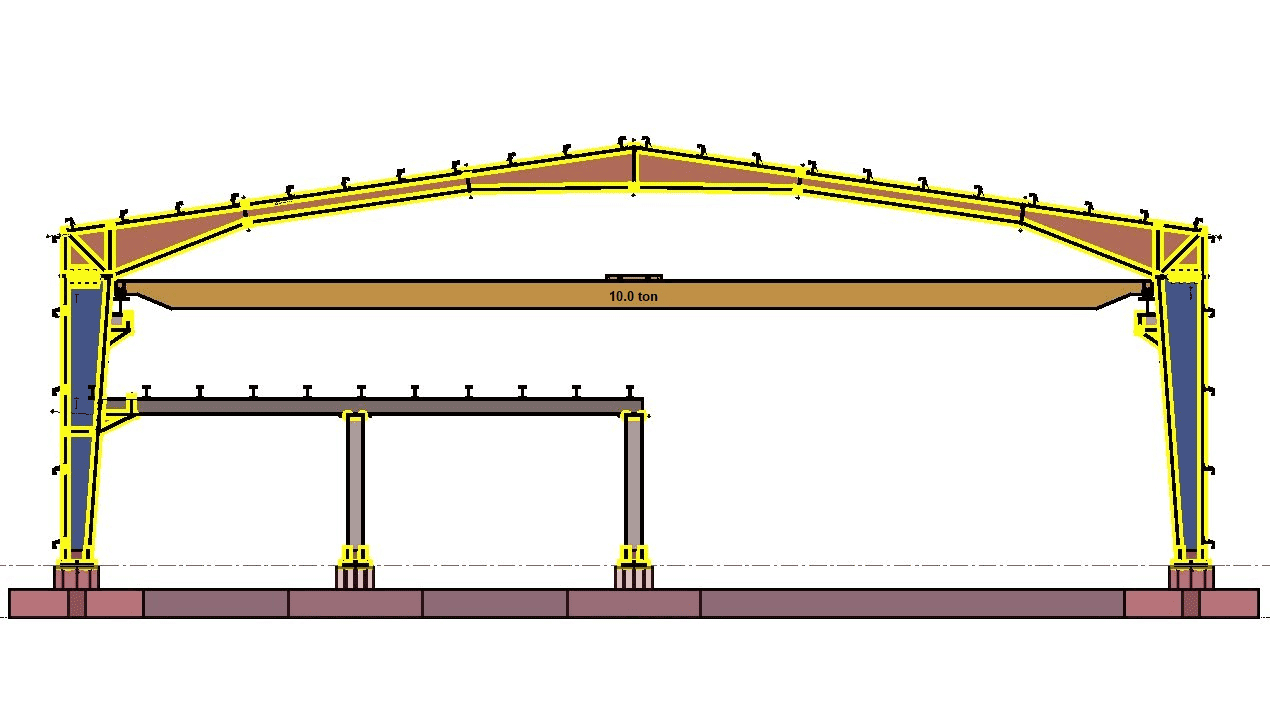

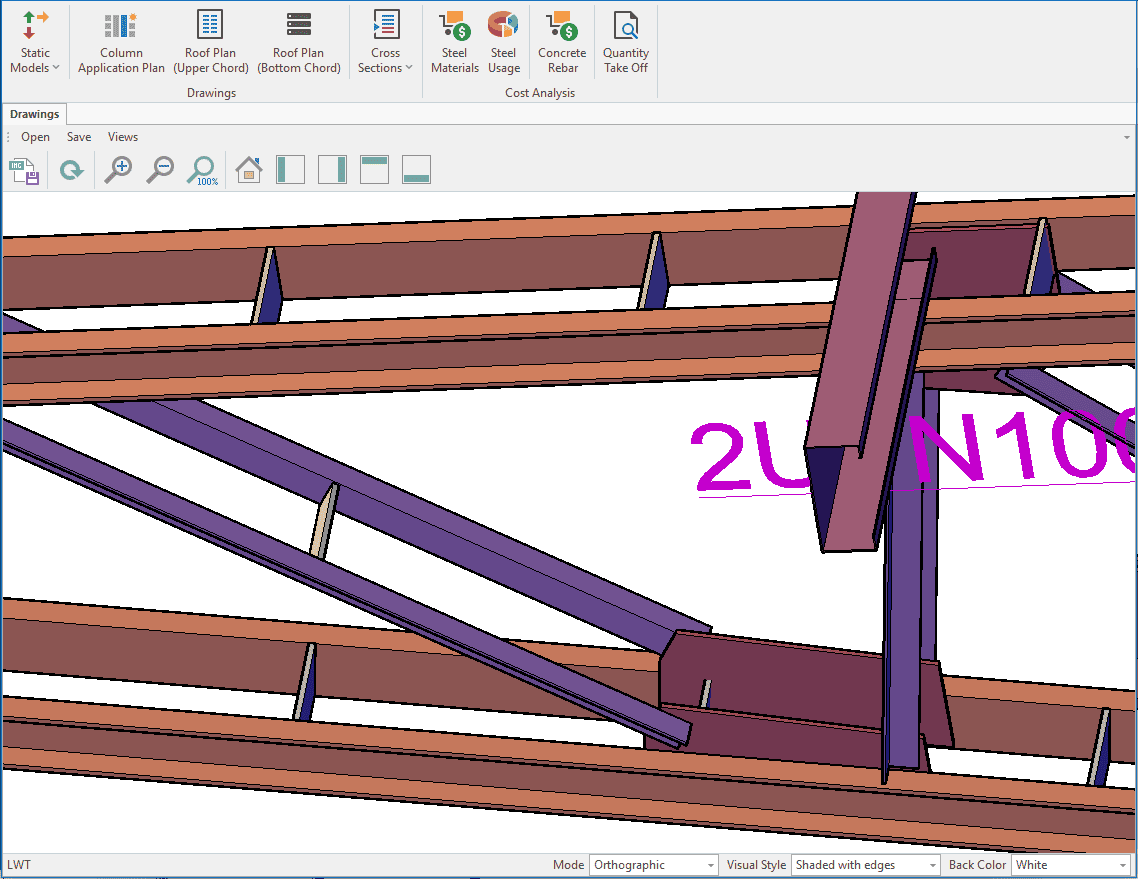

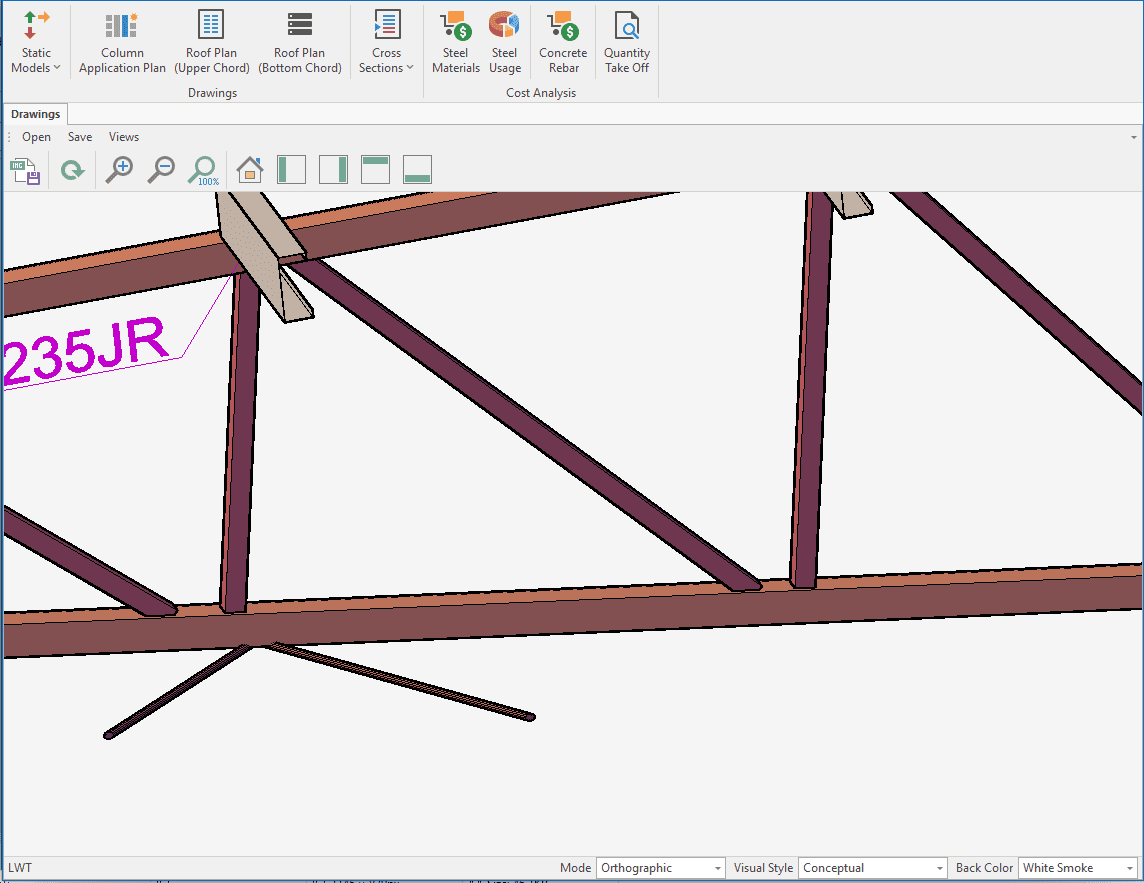

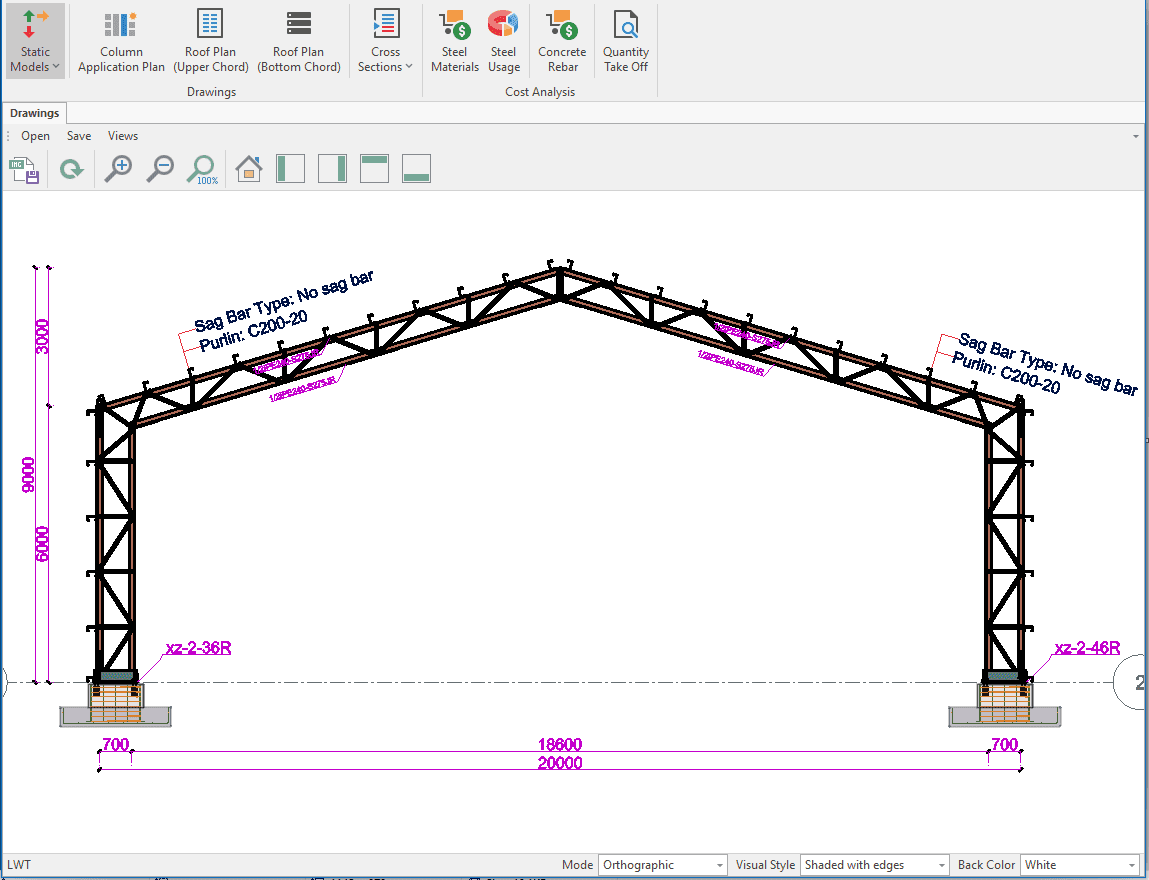

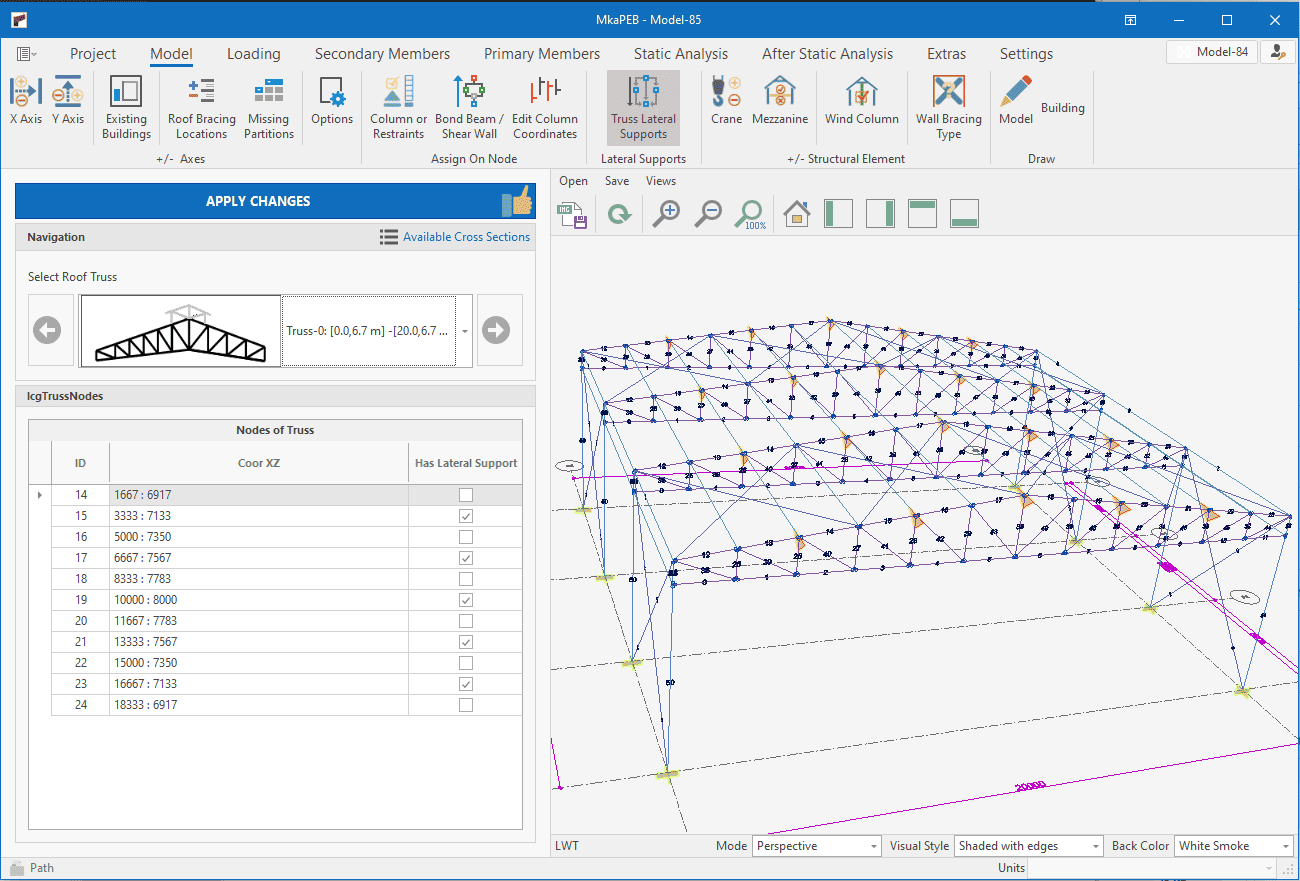

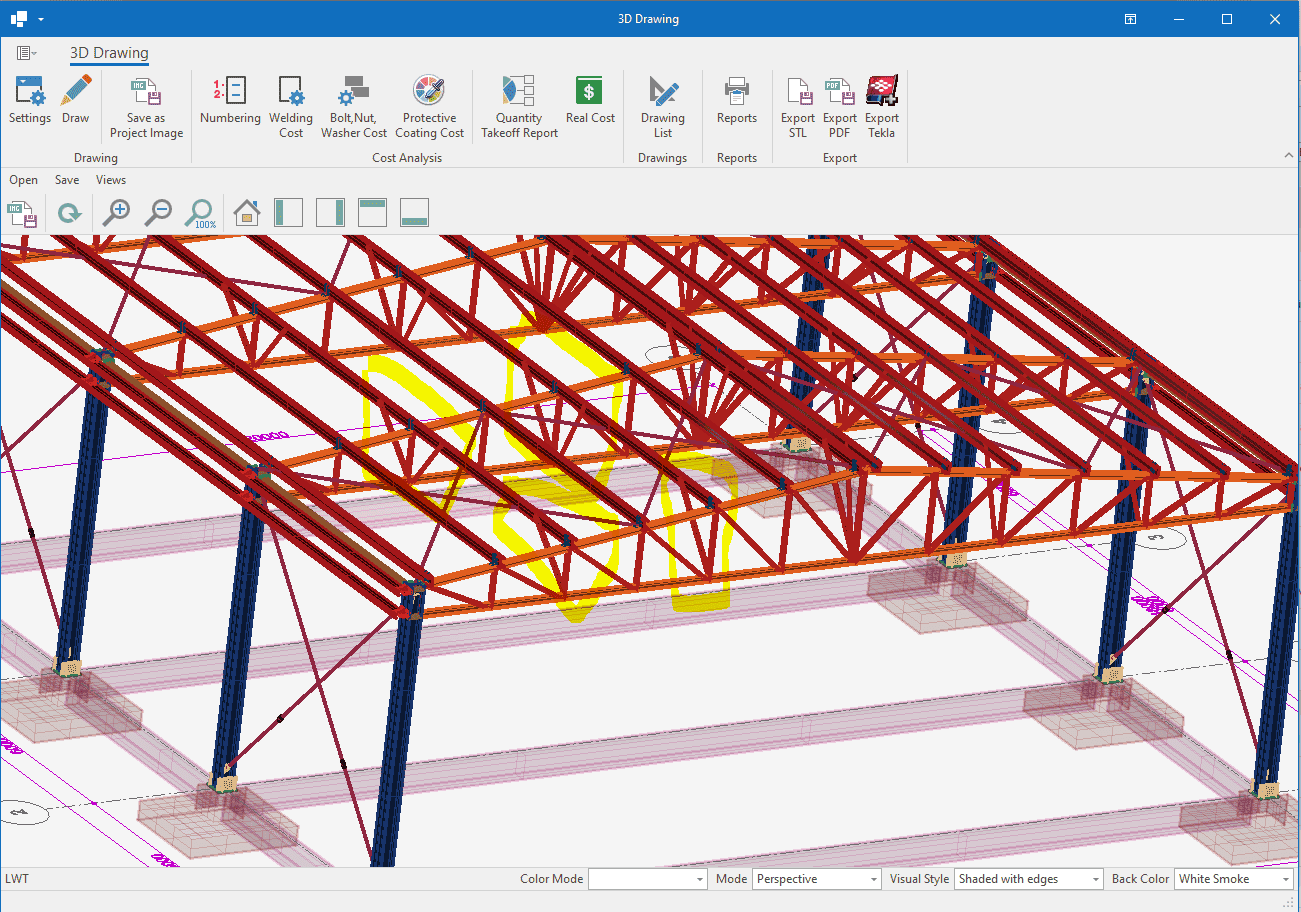

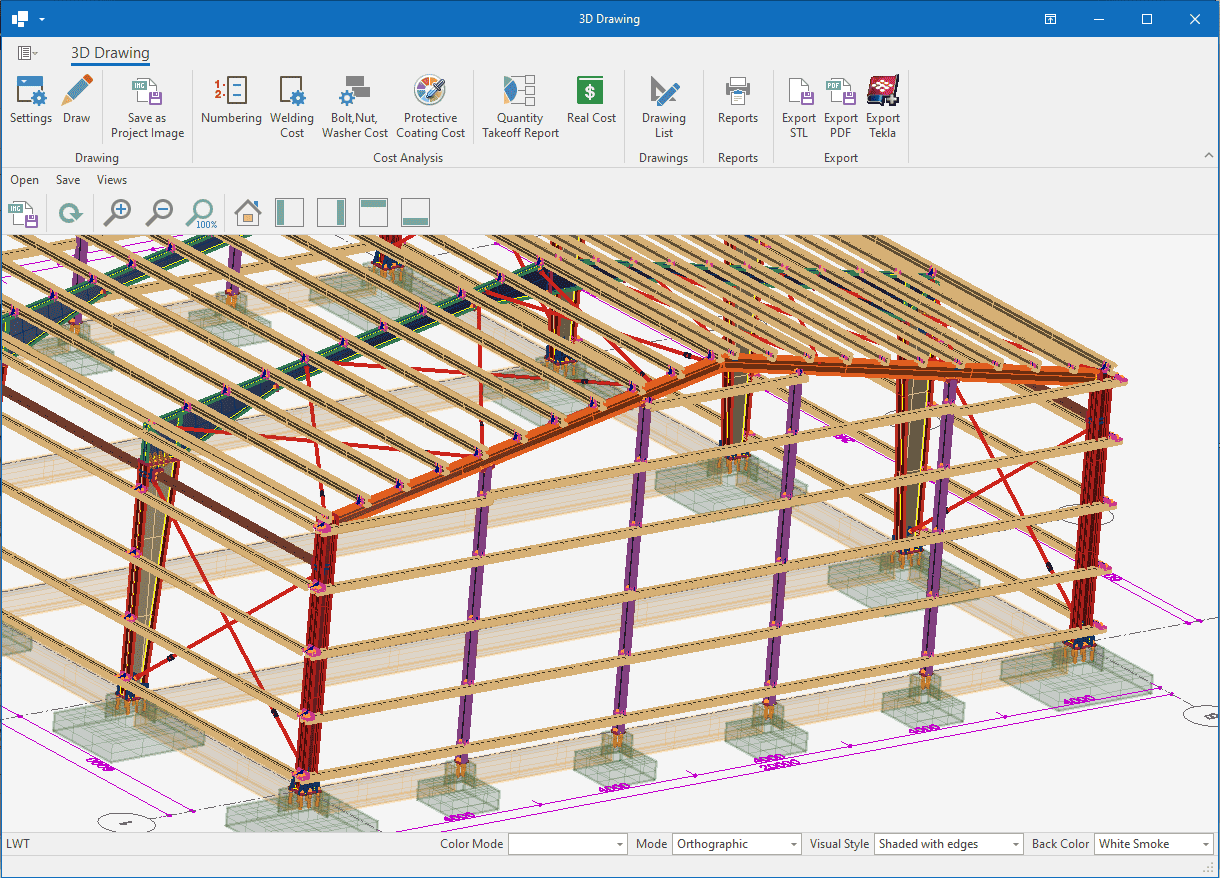

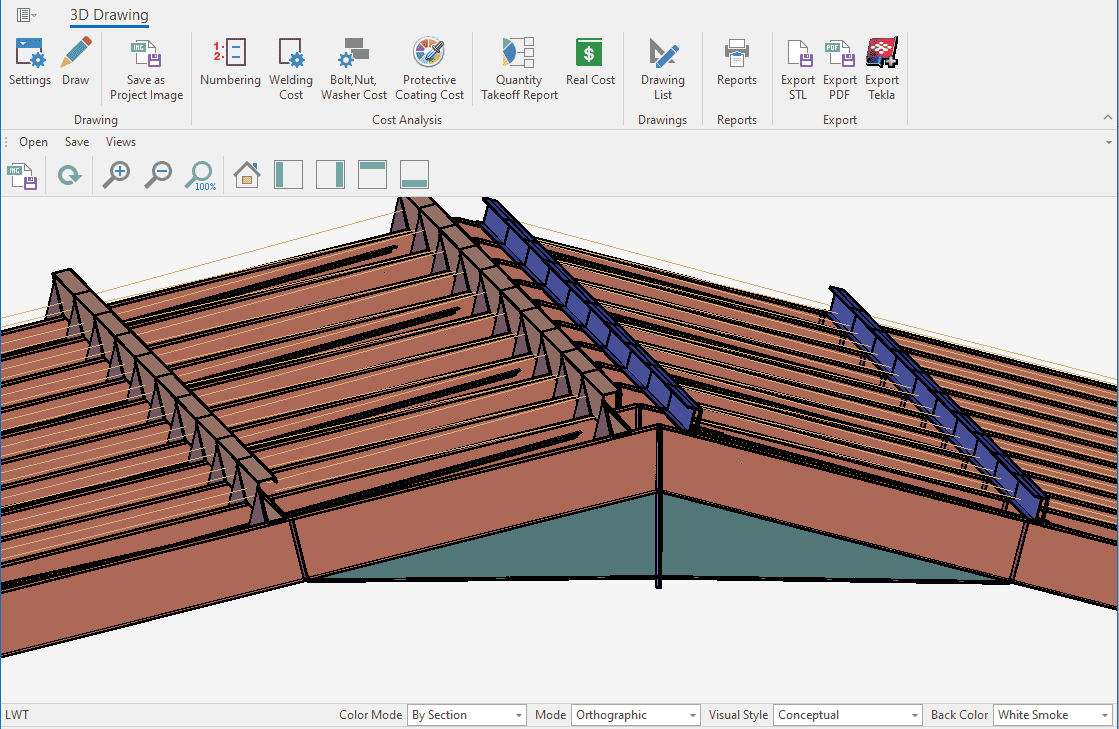

C- TRUSS BUILDINGS

When we think of steel buildings, we immediately think of steel truss structures. Steel trusses have been used for decades to span large distances. In periods when rolled profiles were not common, they were the go-to choice for warehouse roofs, aircraft hangars and factories. While their numbers are on the decline due to manufacturing time and labour costs, it's important to recognise the economic benefits they provide. We believe that a good steel software must have a steel truss alternative such as MkaPEB.

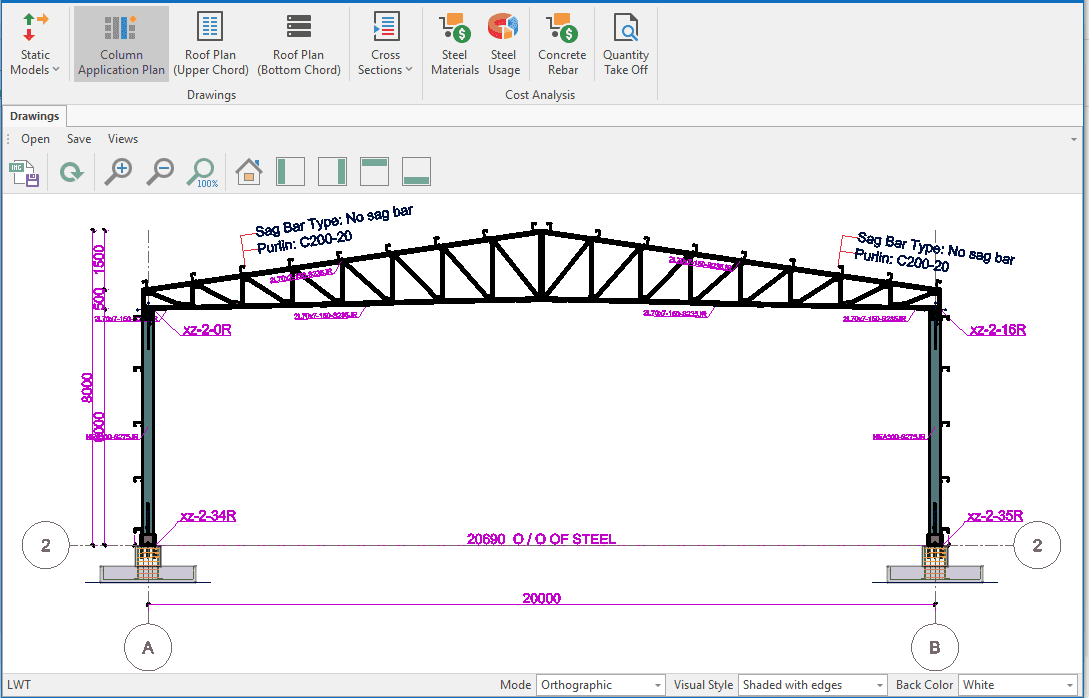

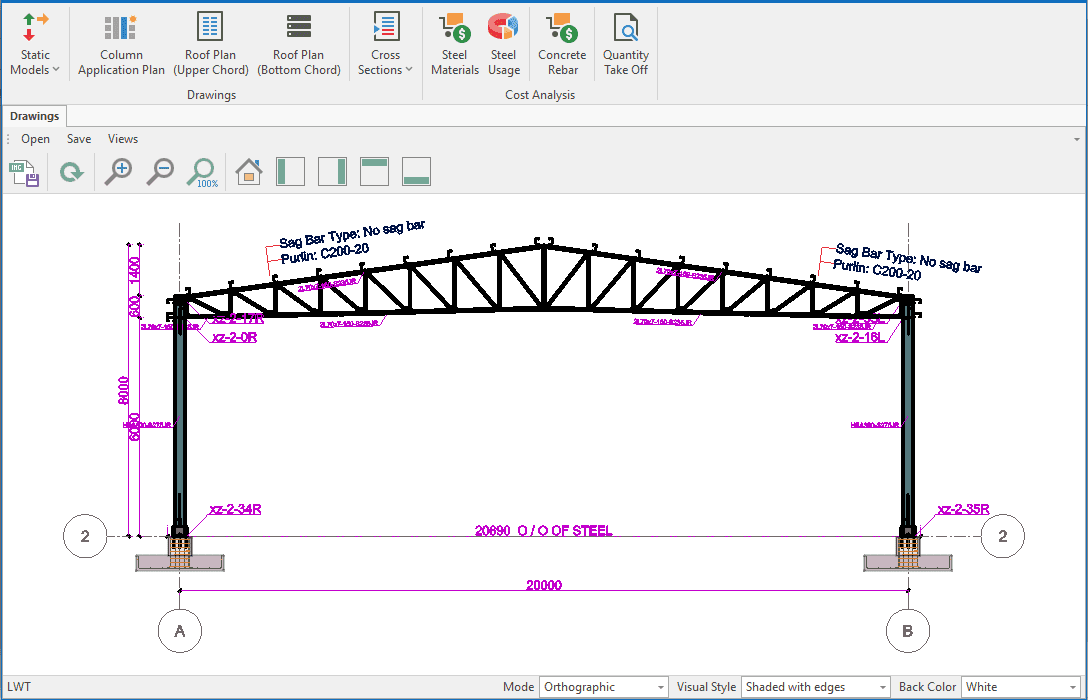

1- Truss Building column types

In steel truss structures, it is often preferable to use different column types. Columns can be either steel or reinforced concrete. If a more economical solution is required, reinforced concrete can be used up to a certain height, followed by steel.

Steel trusses can be mounted on the columns or connected to them from the side, according to the specifications of the project.

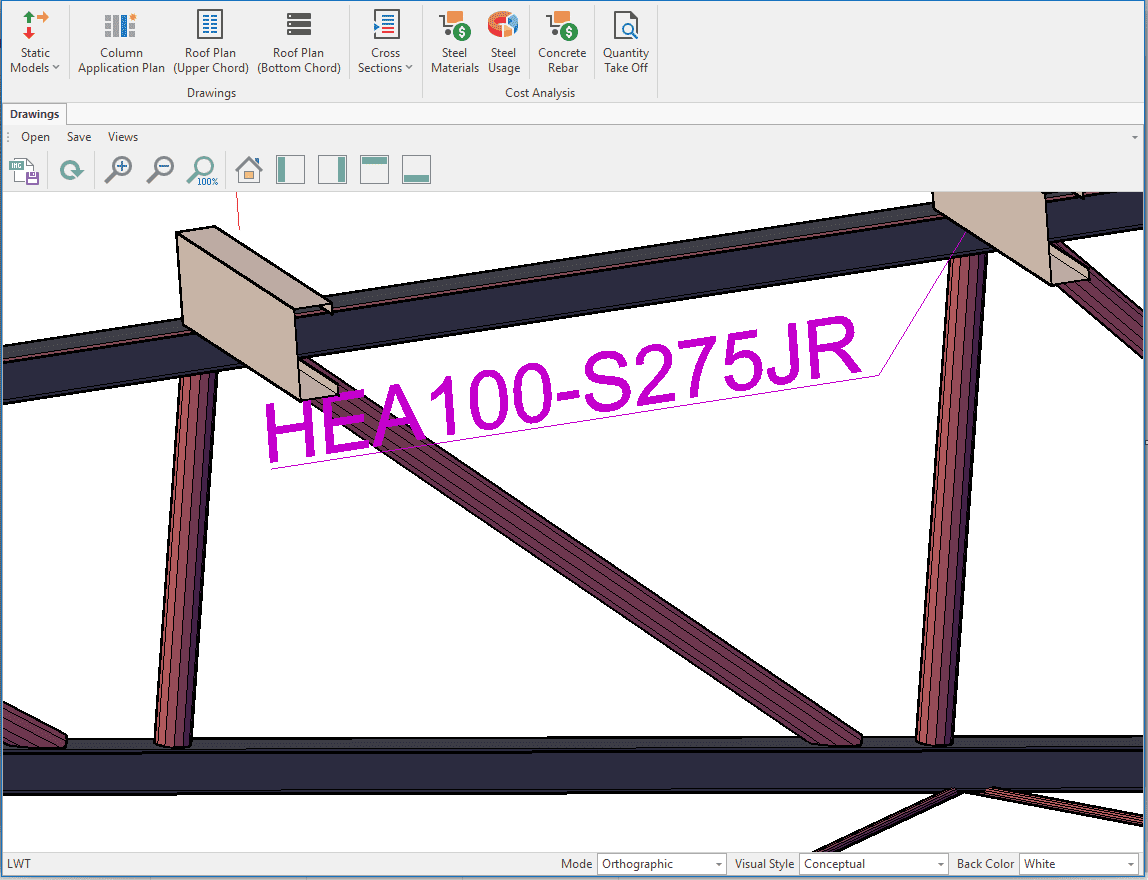

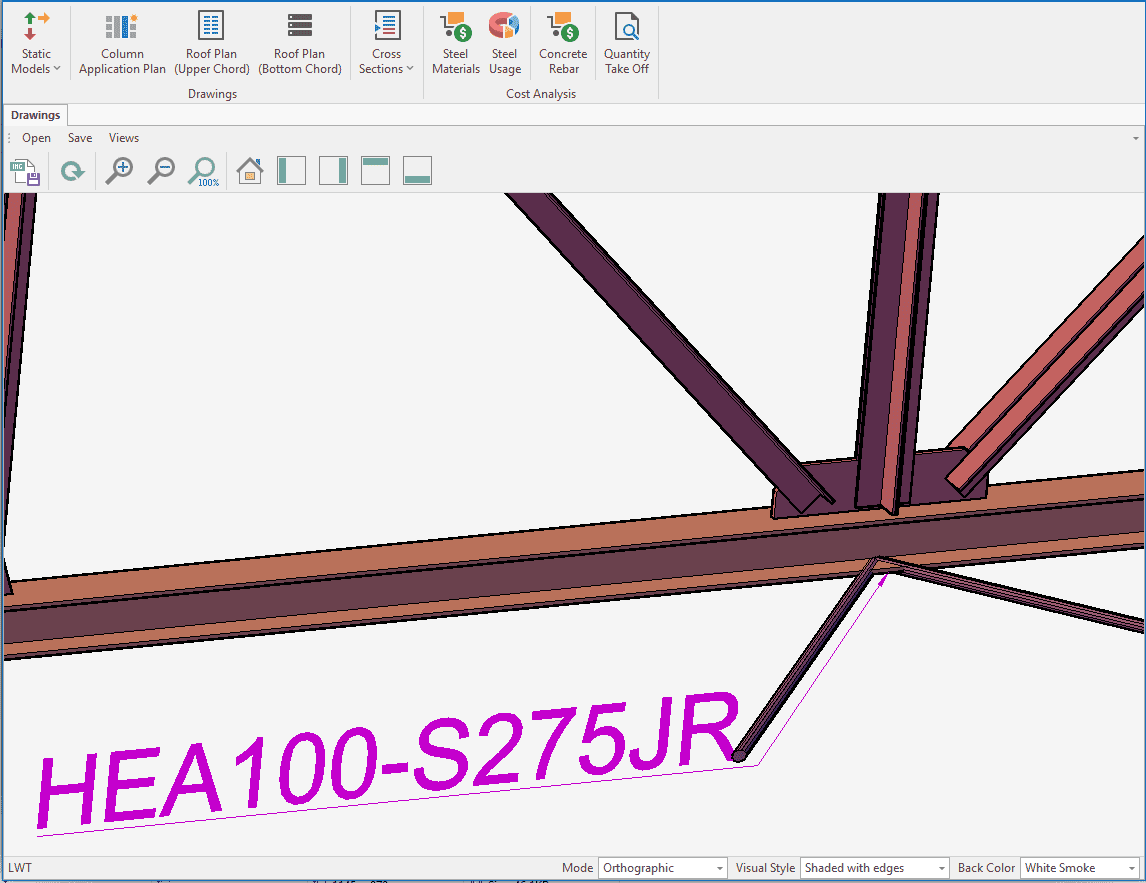

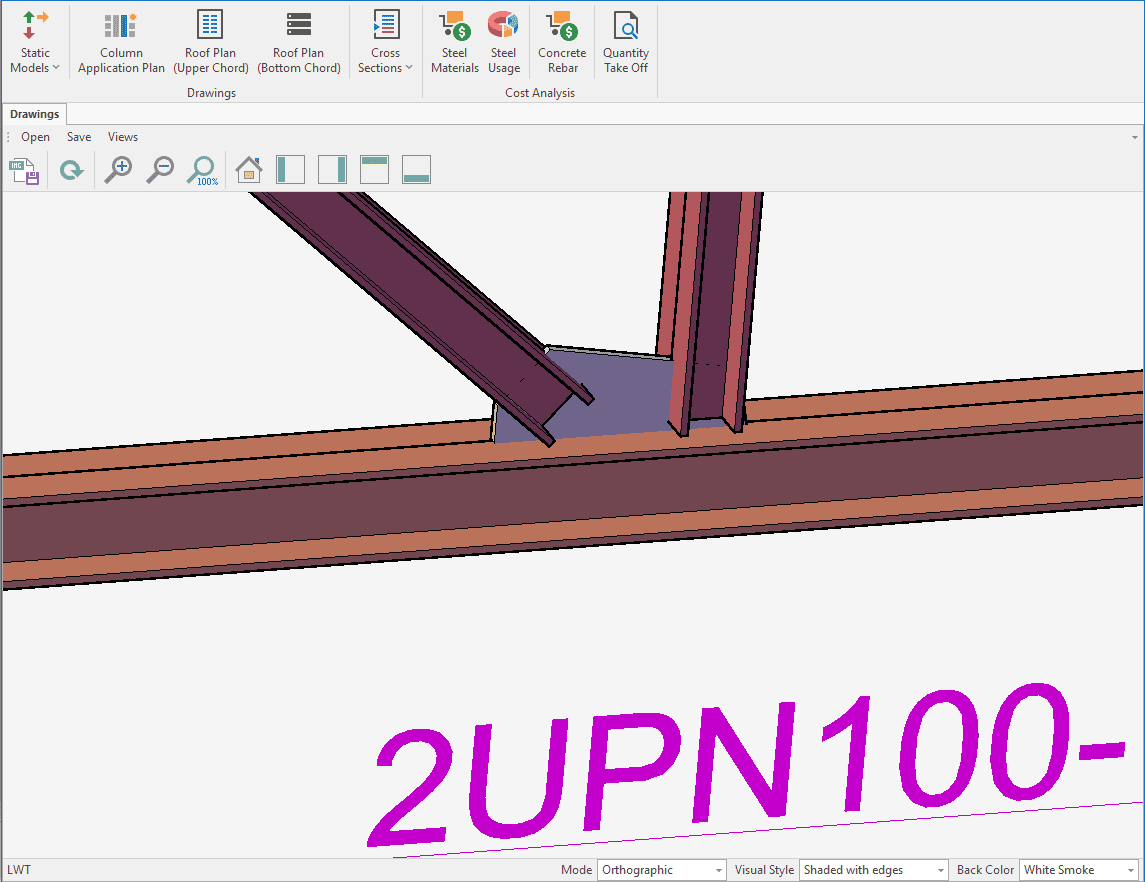

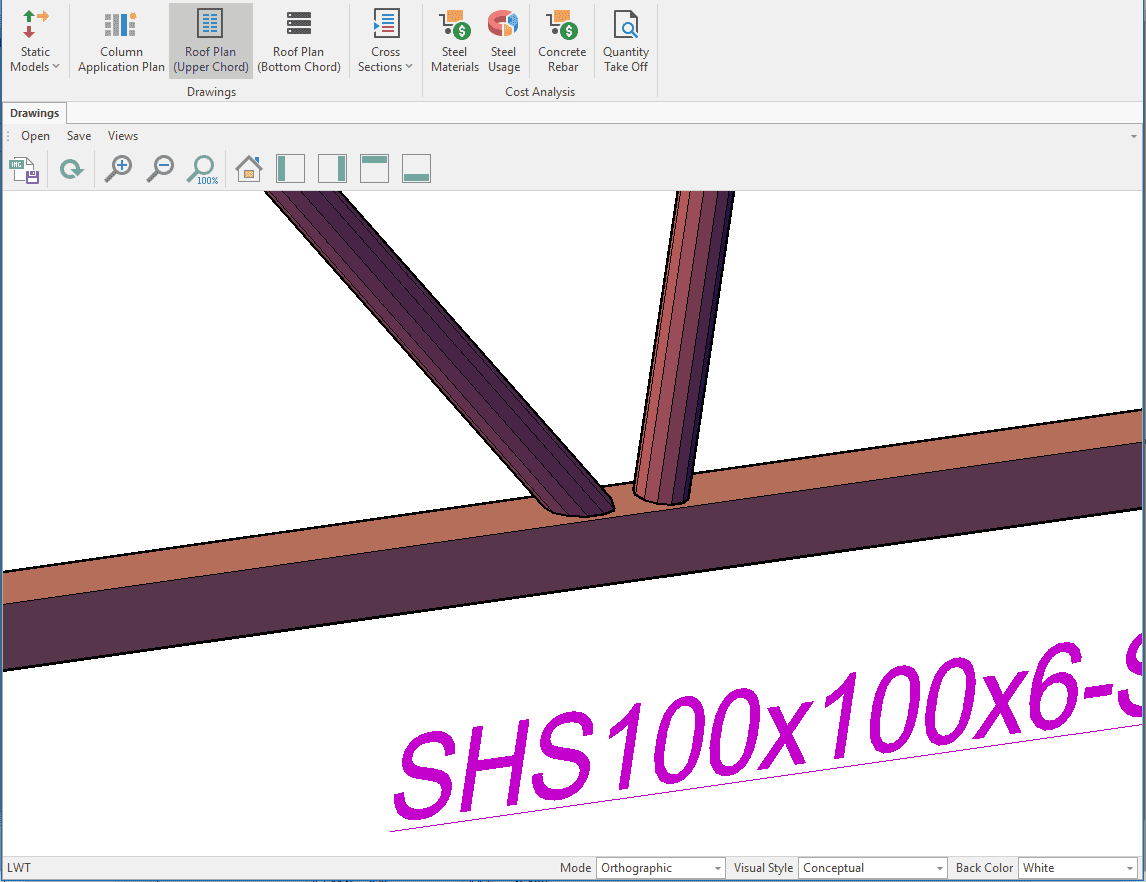

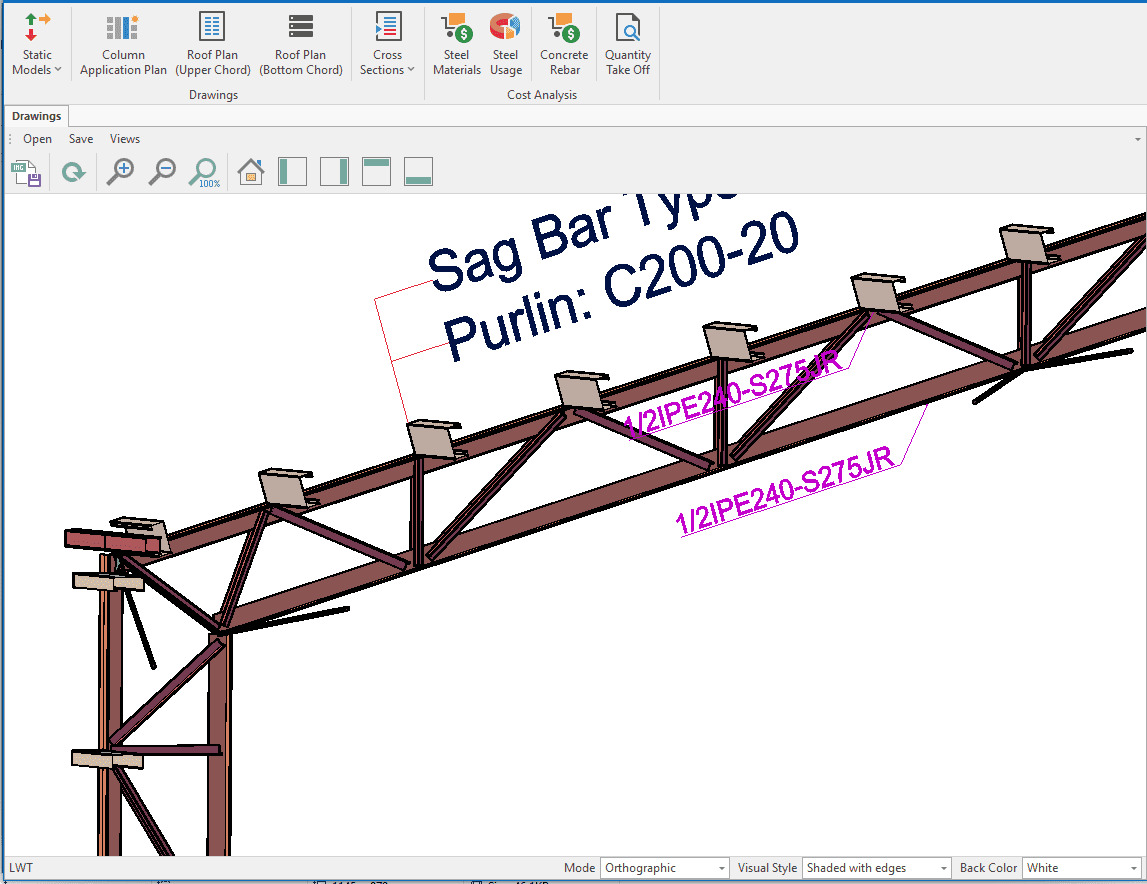

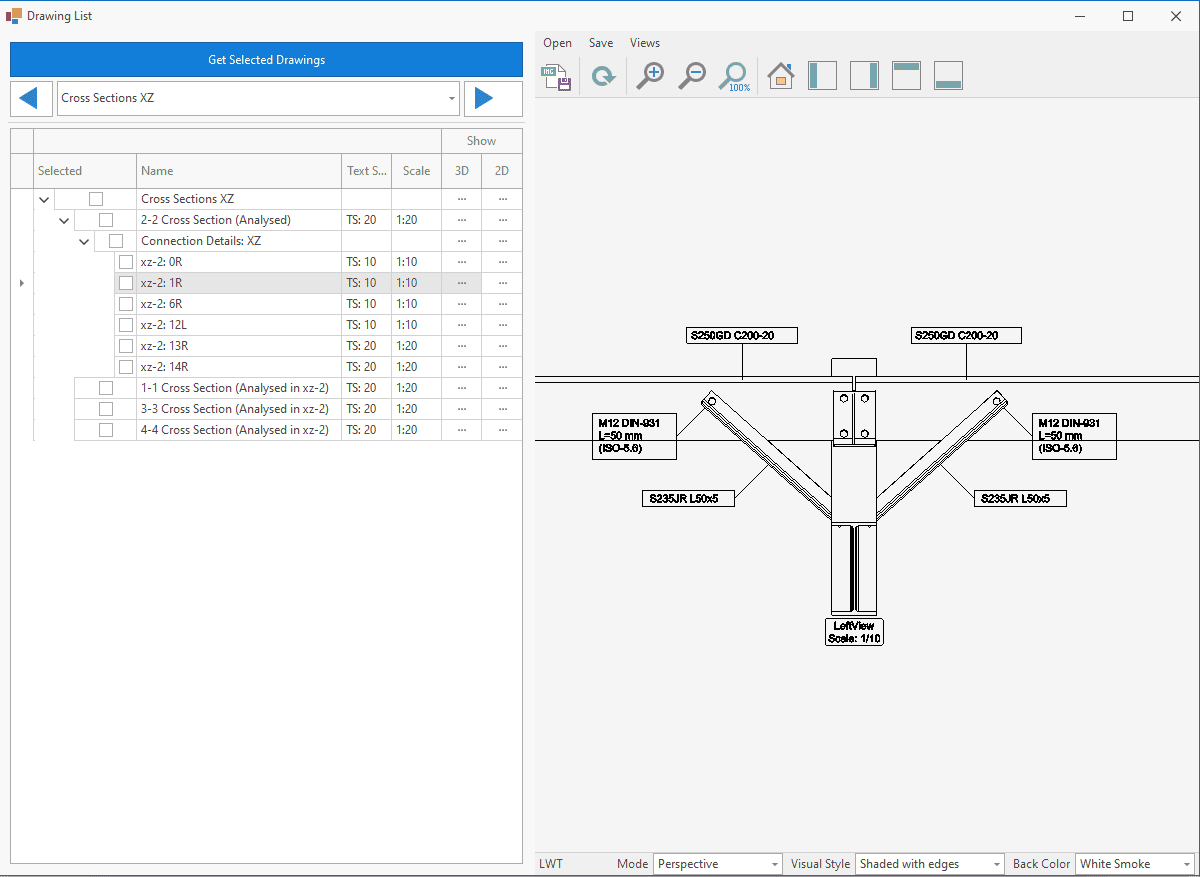

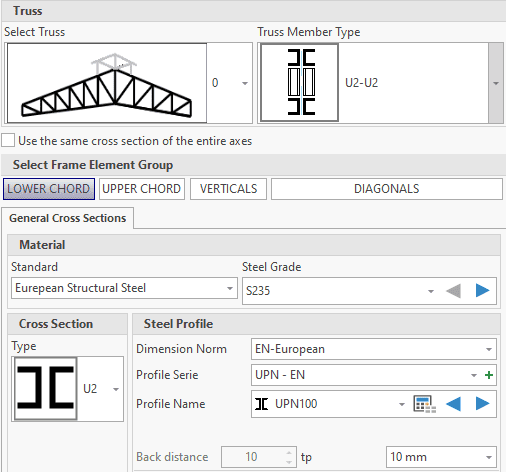

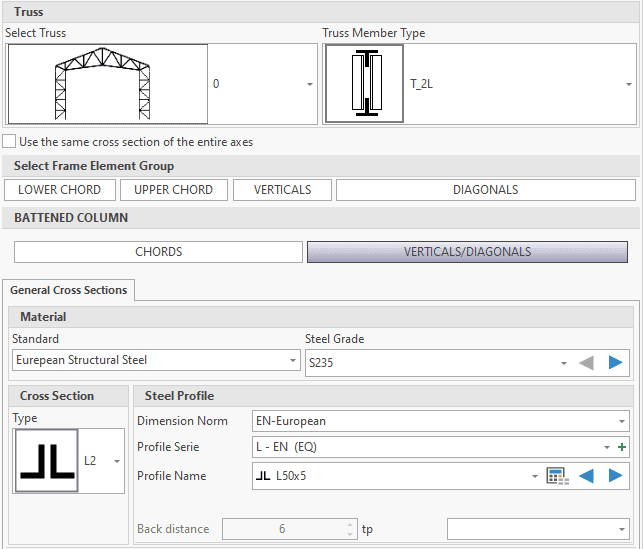

2- Cross Section of steel truss

Steel trusses can be manufactured from a variety of profiles in different forms. The availability of the material is often a key factor in this decision. L and U profiles are more cost-effective than RHS and CHS profiles. 2L, 2U or T profiles are often preferred for lower and upper chords. Some architects believe that CHS or RHS profiles offer a more aesthetically pleasing solution. In particular, the opening of the dovetail to the uprights and diagonals connected will extend the manufacturing time for CHS lower or upper chords.

Engineers seeking an economical structure will undoubtedly consider the steel truss alternative. MkaPEB has been developed with this specific engineering need in mind.

3- Steel web truss building Building Option

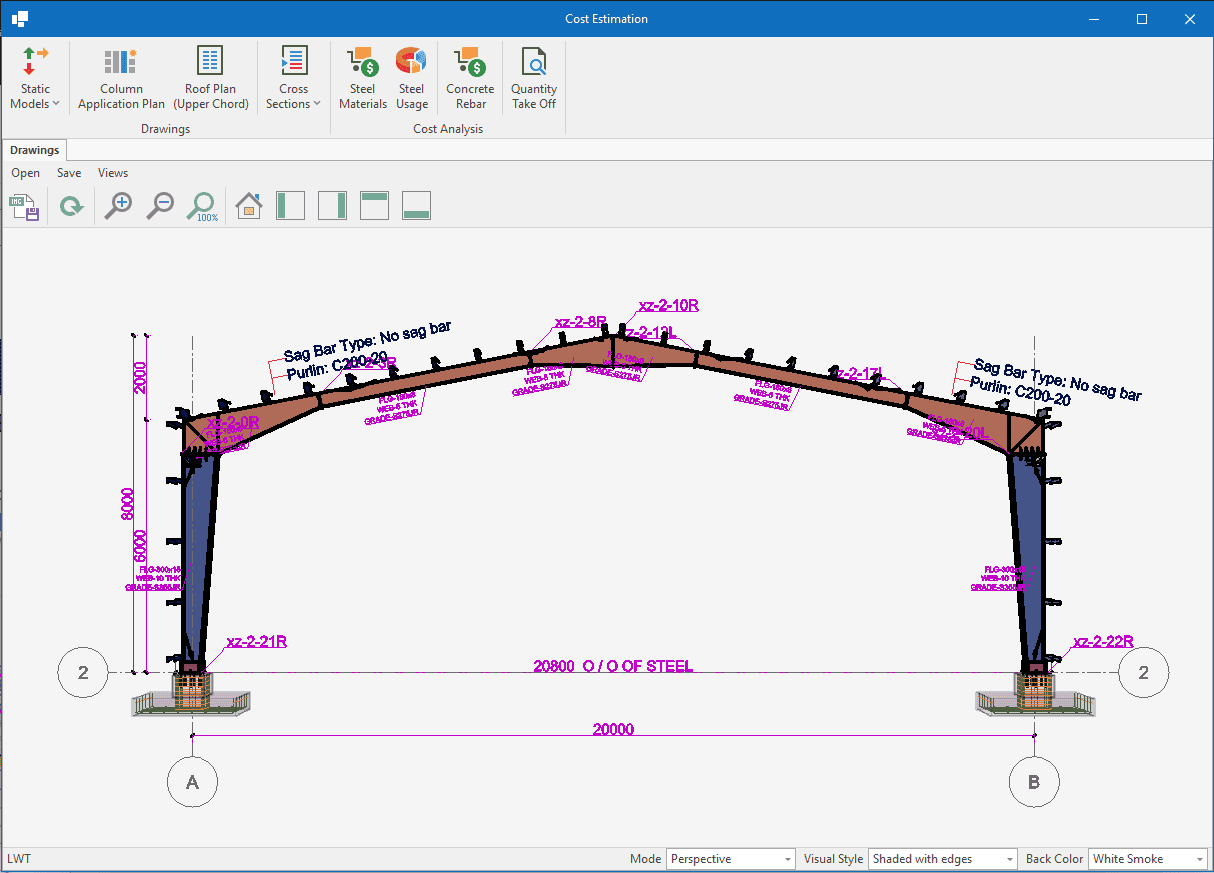

In straightforward structures such as tennis courts, carpet fields, and temporary storage areas, portal truss frame types are the optimal choice due to their minimal weight.

MkaPEB offers ready-made templates for modelling such structures, which enable users to achieve results in a very short time.

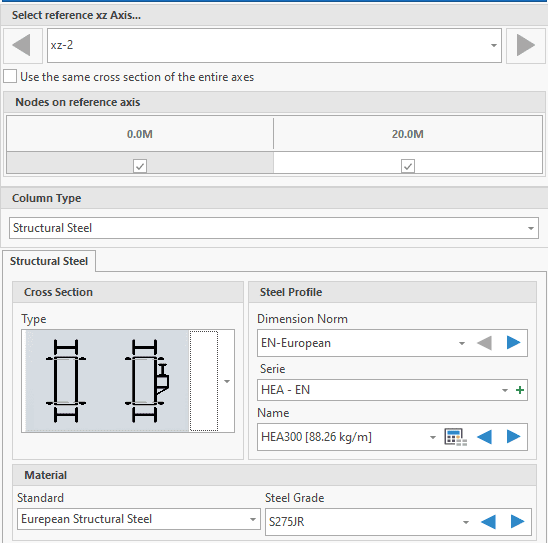

Post and Beam Endwall (PEB)

The Post and Beam Endwall is a great, economical end frame that's designed to make the most of cold-formed, hot-rolled and welded-up plate posts (columns) and beams (rafter). The beams are simple span between all end posts, including corner posts, with bolted clip connections at each end.

The single-storey steel warehouse structure has wind columns on the front and rear facades. And this axis receives less snow and wind load than the intermediate axis. Therefore, savings can be made by using smaller sections in the axis. Today, many PEB manufacturers have adopted this method. This feature has been added to MkaPEB so that you have no difficulty in competing with these companies.

We should have the advantage of tapered cross-sections

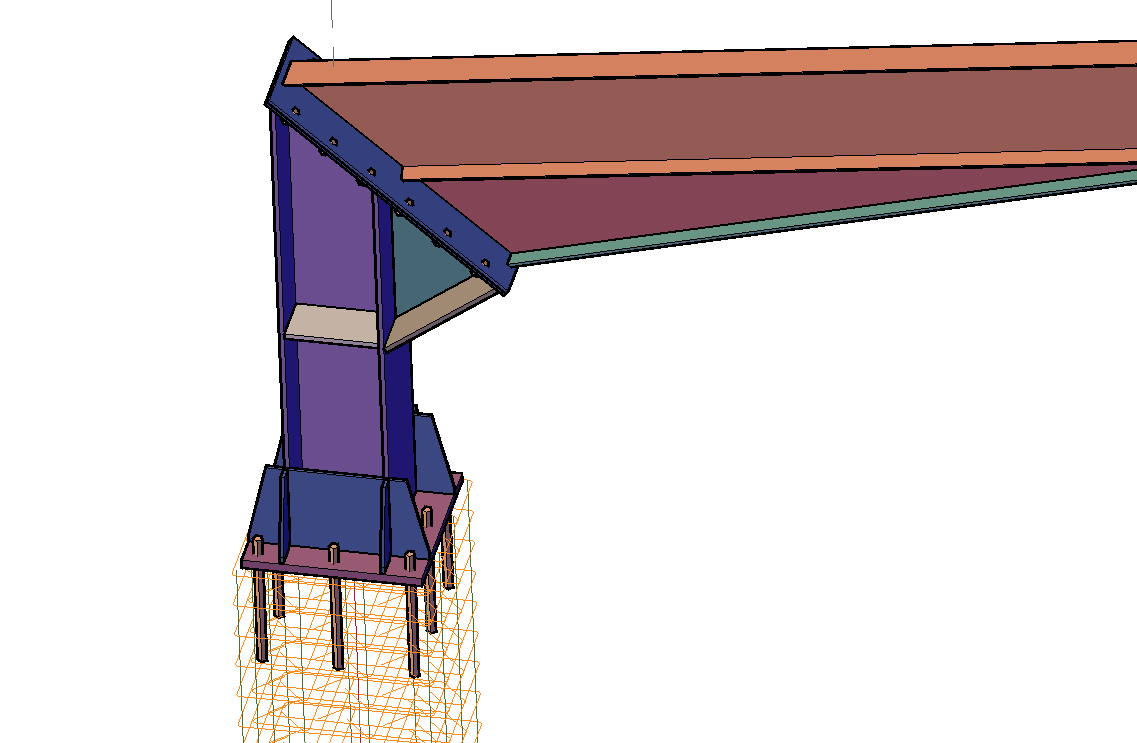

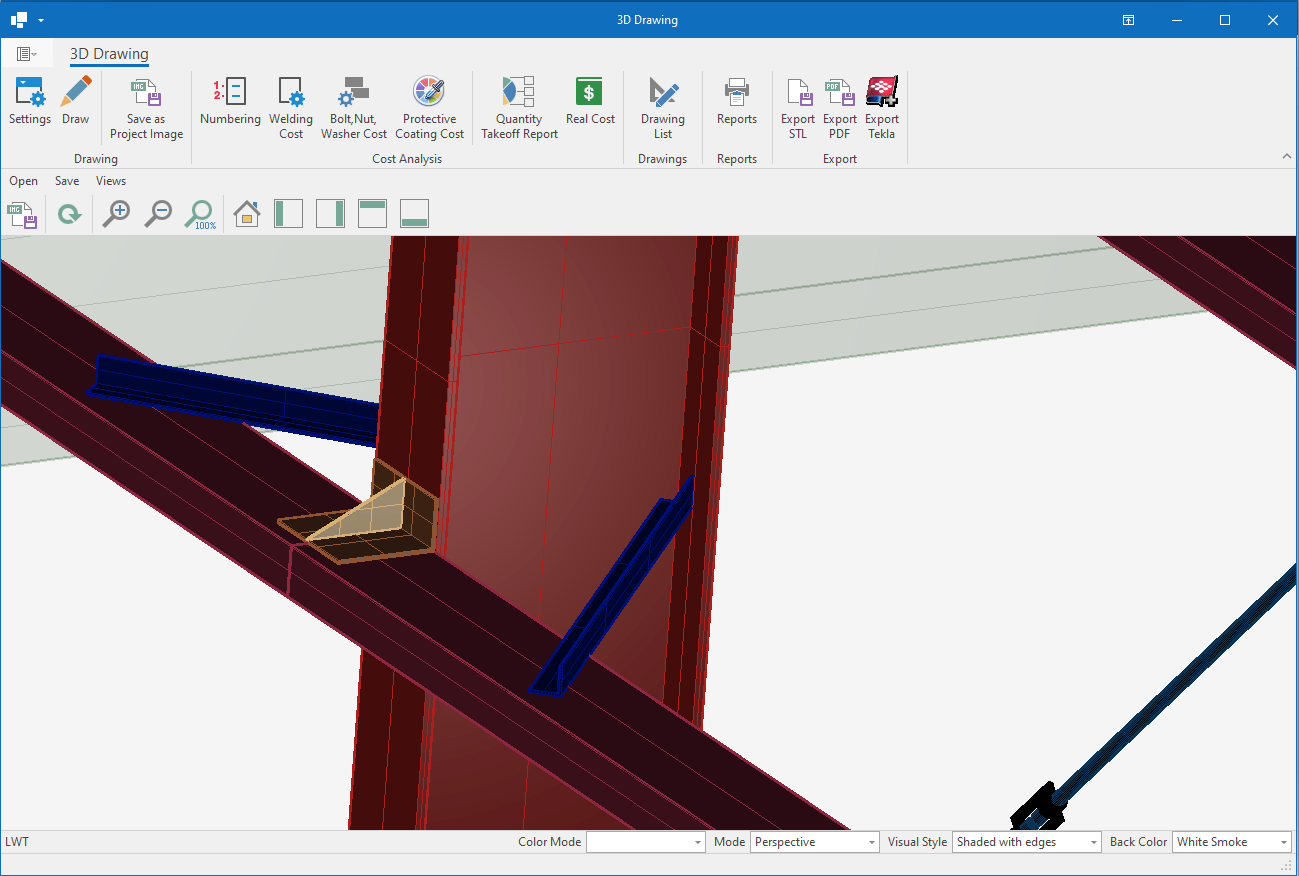

Portal frame bolted end plate connection haunches

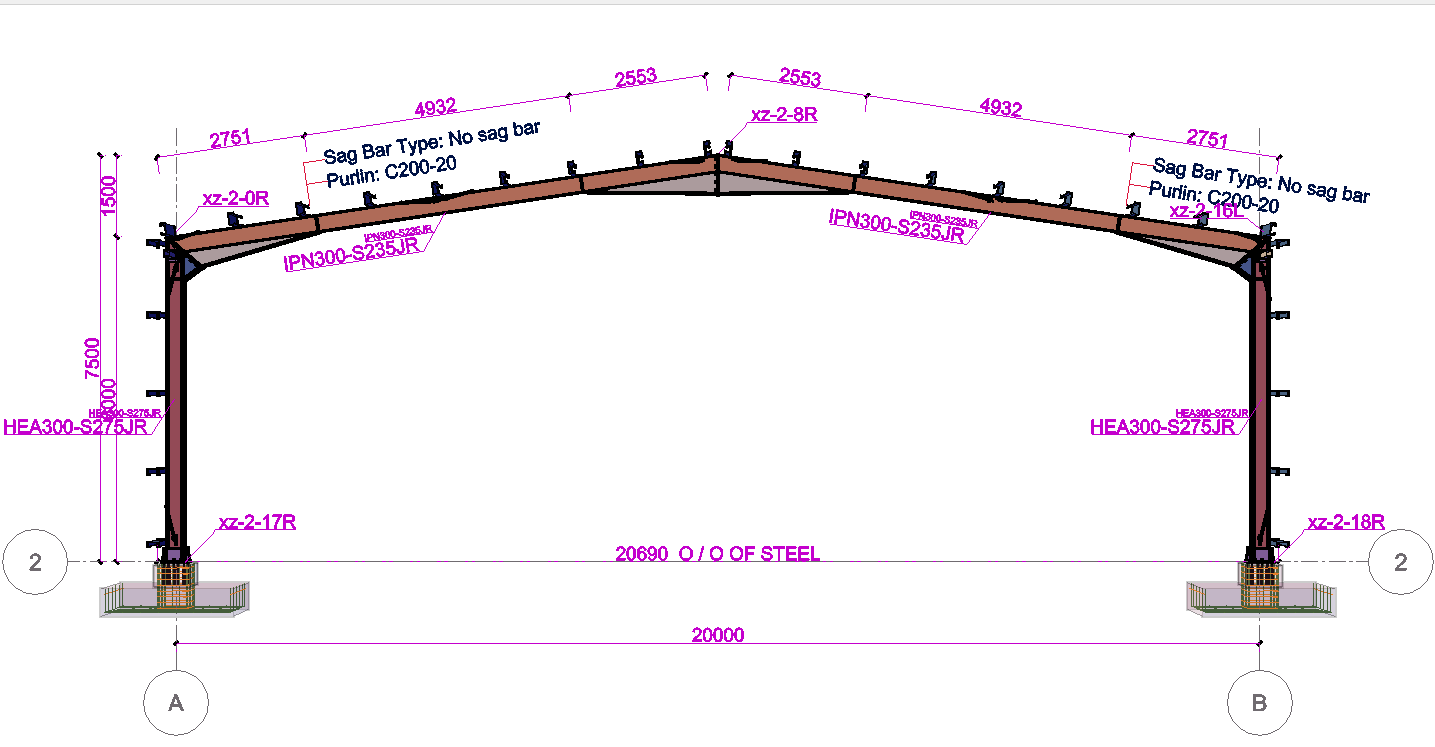

When making moment-resistant bolted end plates or welded connections at the corner and ridge points of portal frames, we increase the beam cross-section at this point. This is the best way to ensure the beam is able to withstand the required forces. This is often necessary for connection design.

Furthermore, we know that the greatest value of the moment in portal frames is at the corner and ridge points. This moment value often determines the beam cross-section.

By controlling the bending strength of the beam with the beam cross-section that we increase at the corner and ridge for the joint, we can provide economy here.

We will analyse two simple examples to see the economic benefit.

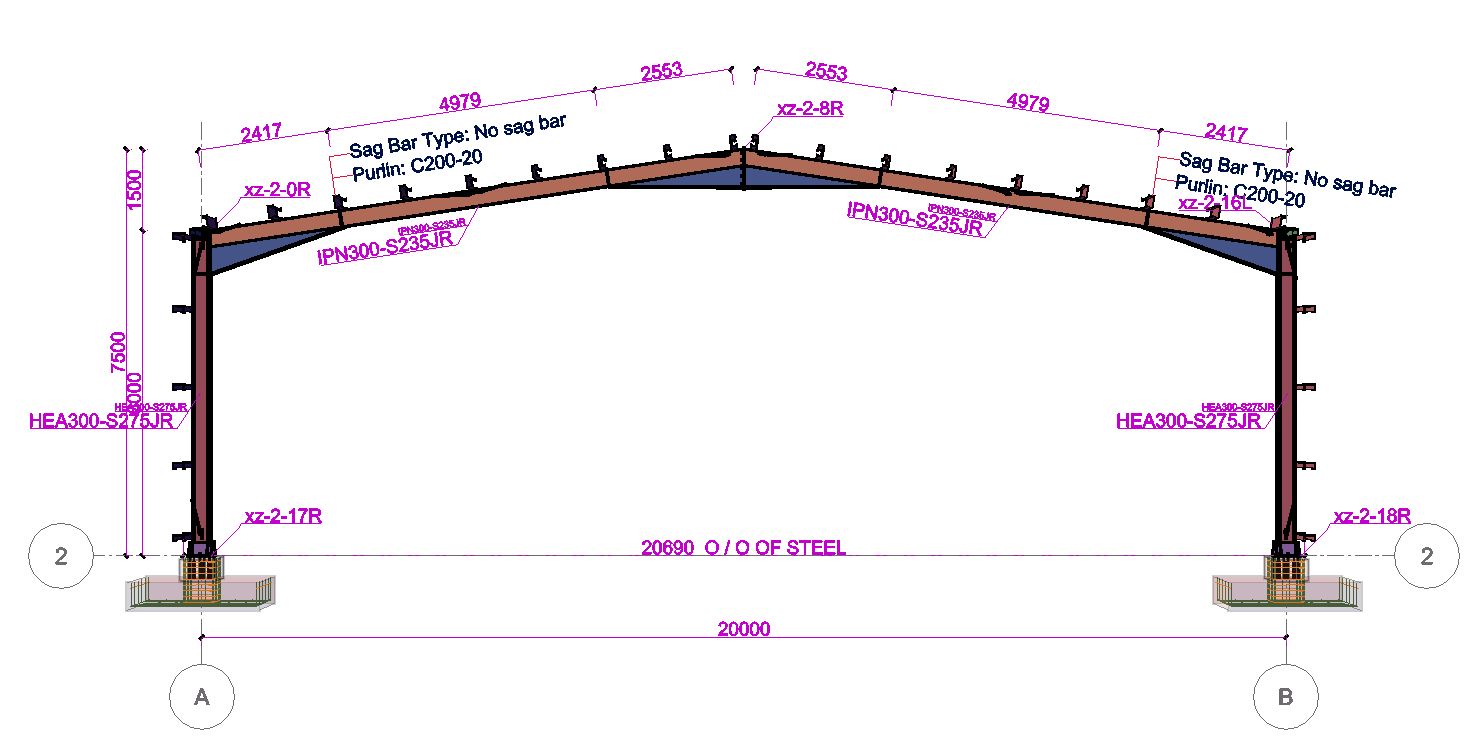

a- In our first model, the beam section will not expand at the corner and ridge.

b- In our second example, in the same steel structure, we will use a tapered section at the corner and ridge.

Without haunches

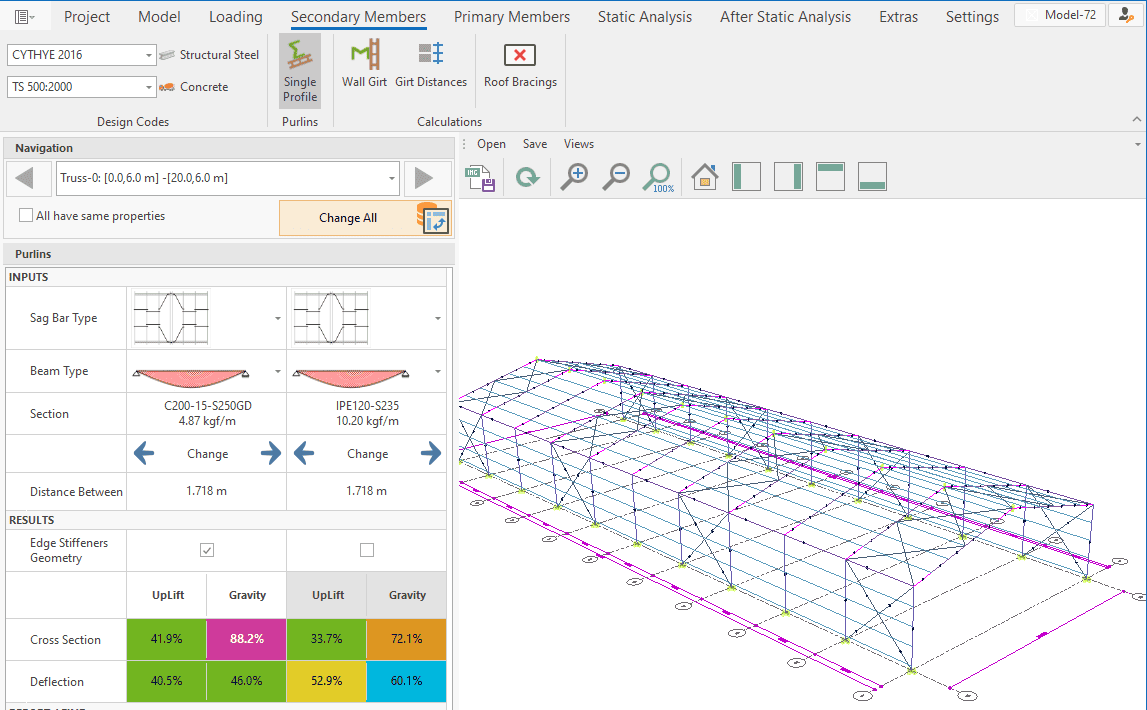

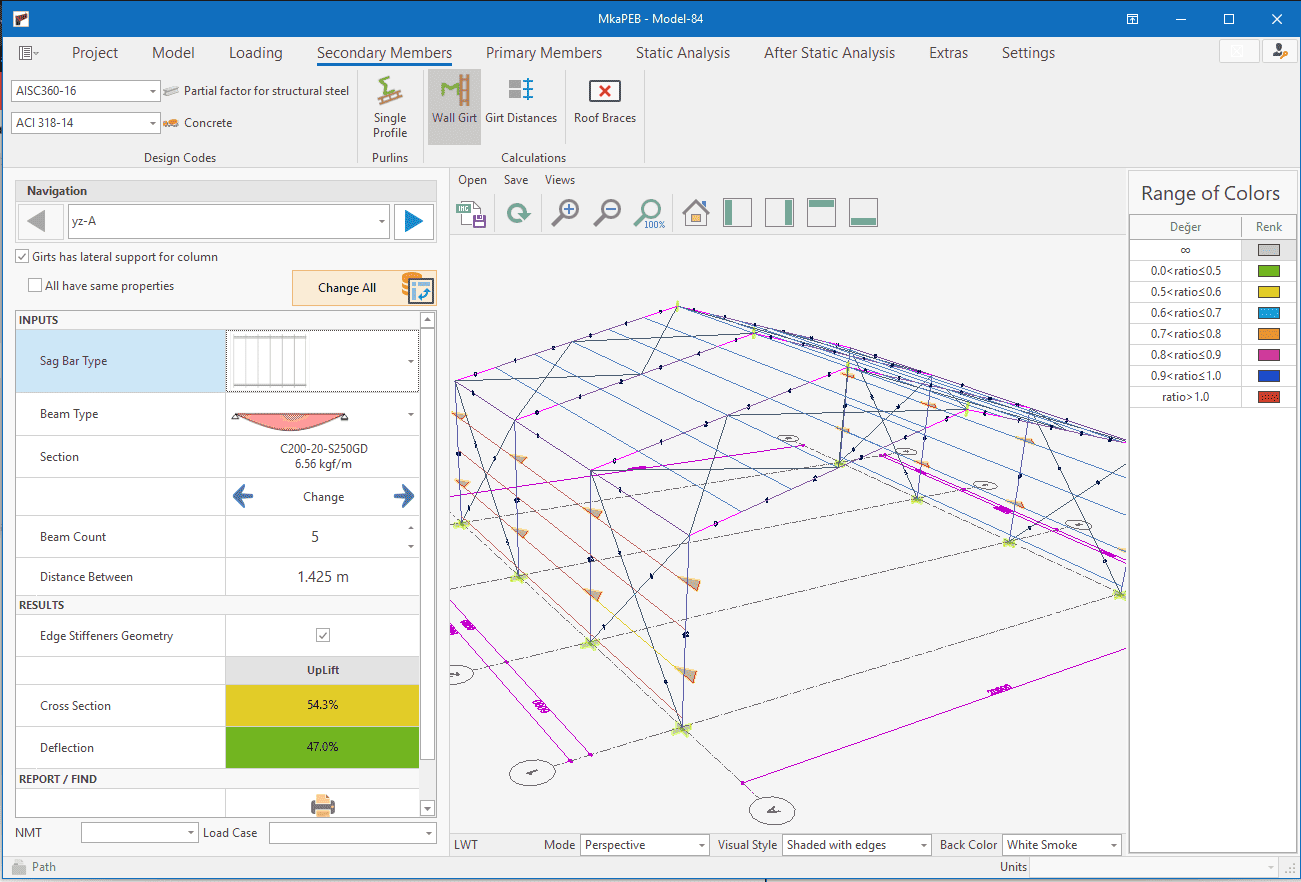

Cold formed purlin and girts

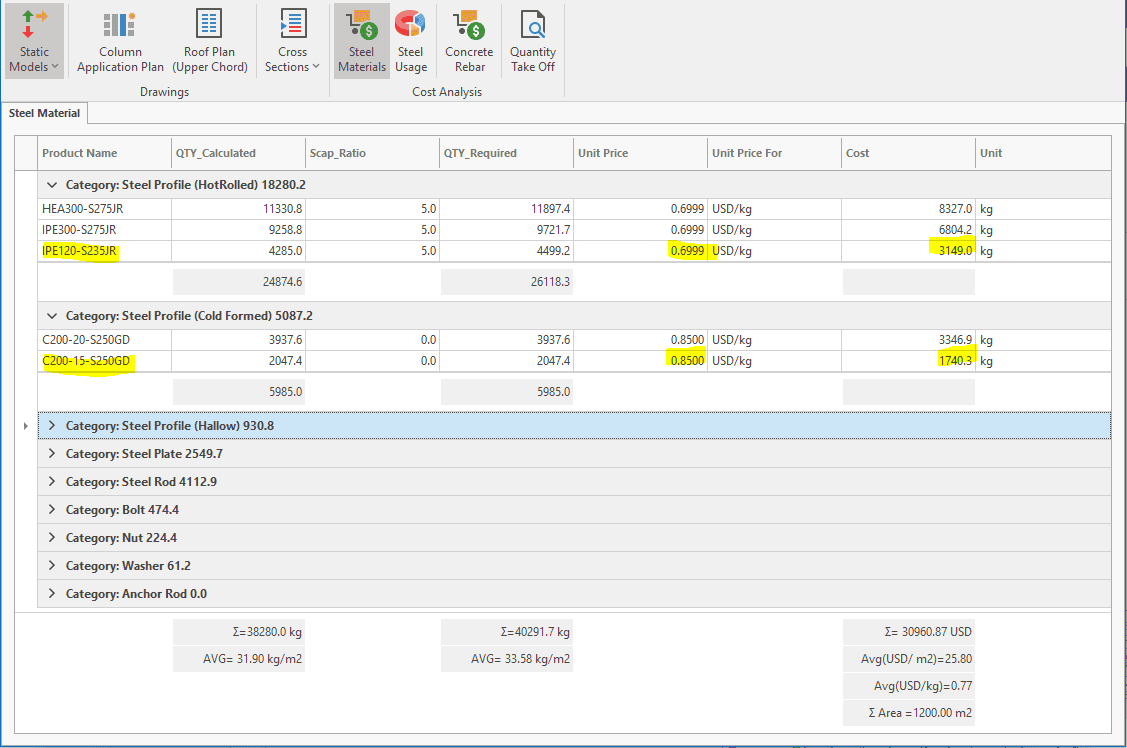

Finding the right material for your project can save you a lot of money while still getting a good result. Cold-formed steel (CFS) framing has a good track record of being cost-effective and sustainable for low-rise buildings, and it's often cheaper than other building materials when you look at the total cost of construction.

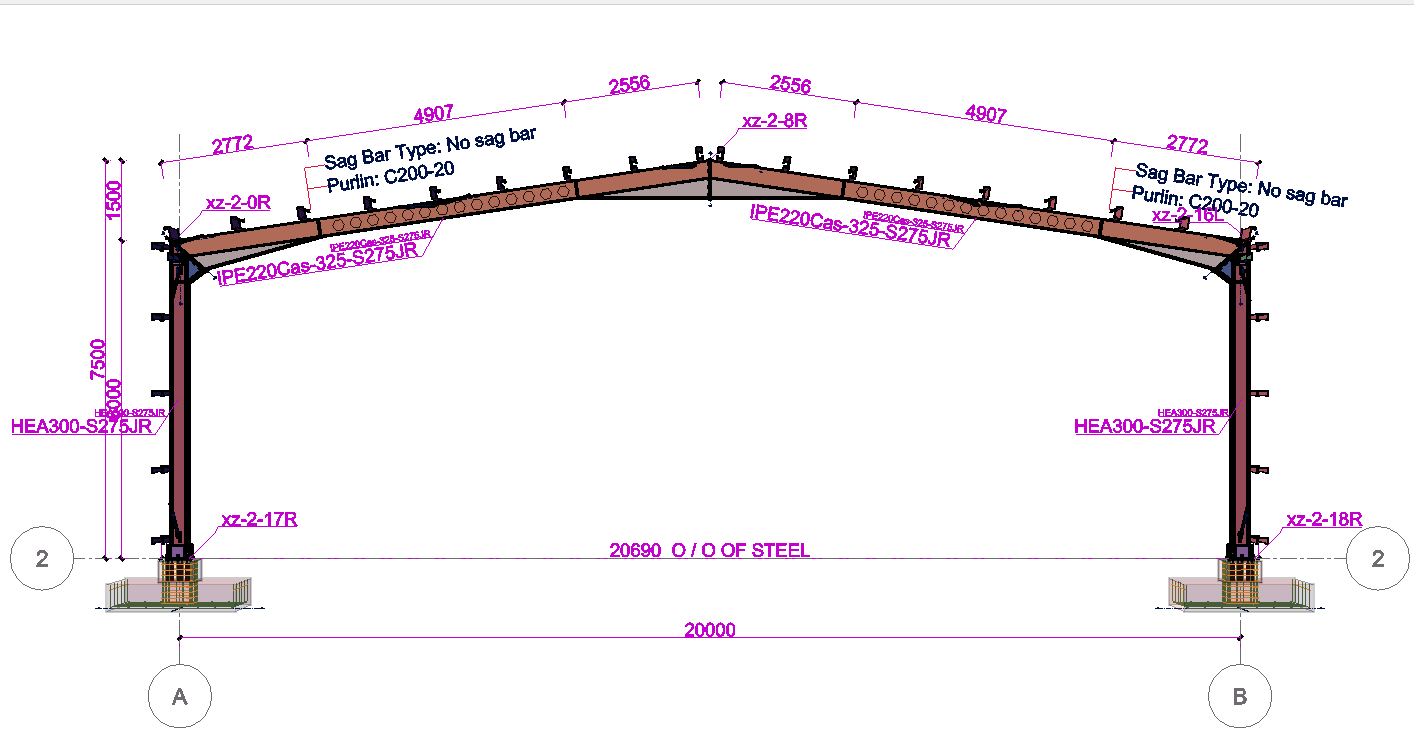

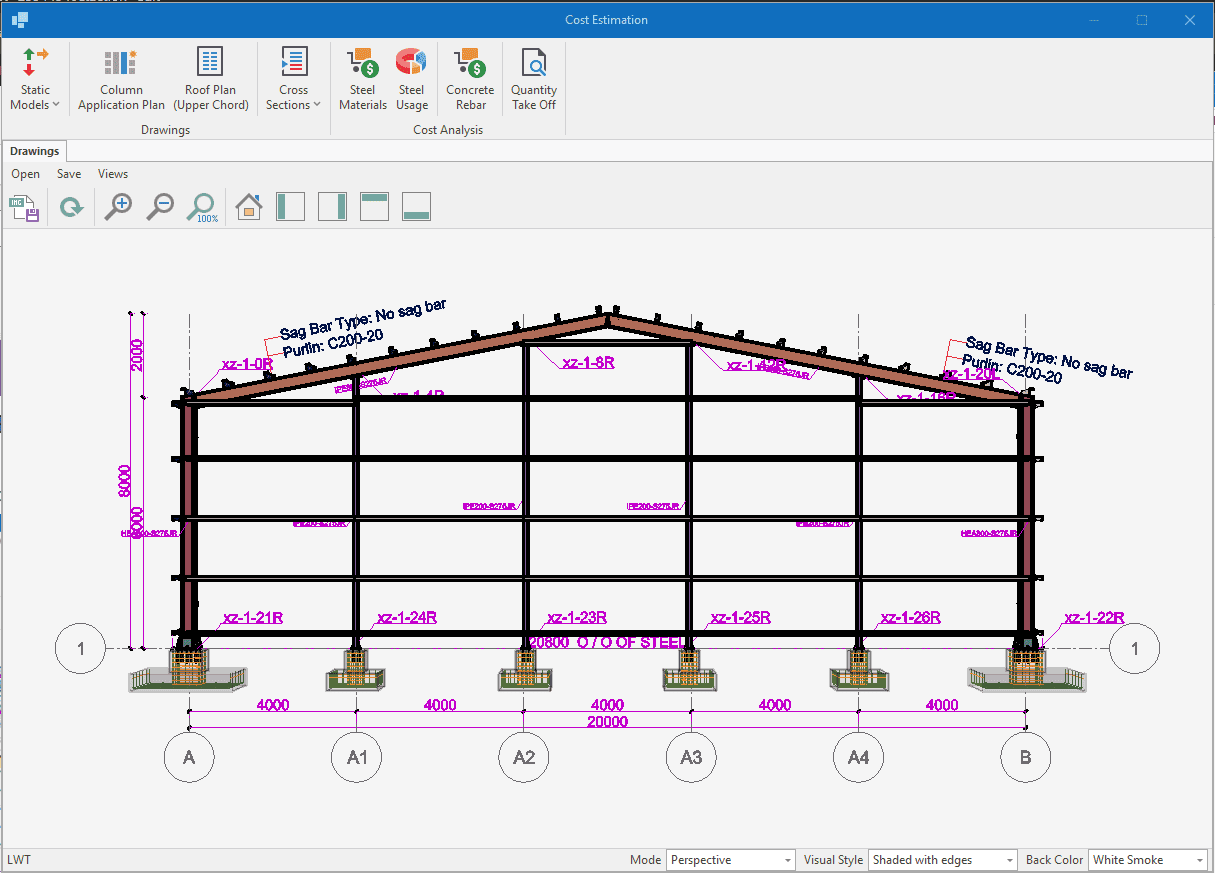

Let's take a look at how cold-formed steel purlins on one side and hot-rolled steel on the other side of a 20x60 duo-pitched roof building compare.

Tension-only bracings

We all know that without bracing, a structure just can't stand up to the wind or seismic activity. It's a part of the building process that's there for a reason! But many traditional bracing systems can be tricky to get right, and take up a lot of time. Tension-only rod bracing is a great alternative – it's quick and easy, and it saves you time, effort, and costs!

Tension-only members are great! They act just like normal members when it comes to axial, flexural, torsional and shear capacity. The only thing is, if they go into compression, they're automatically disabled and act as if they've been removed from the model.

How to model portal bracing with MkaPEB. Let's see this with a short video.

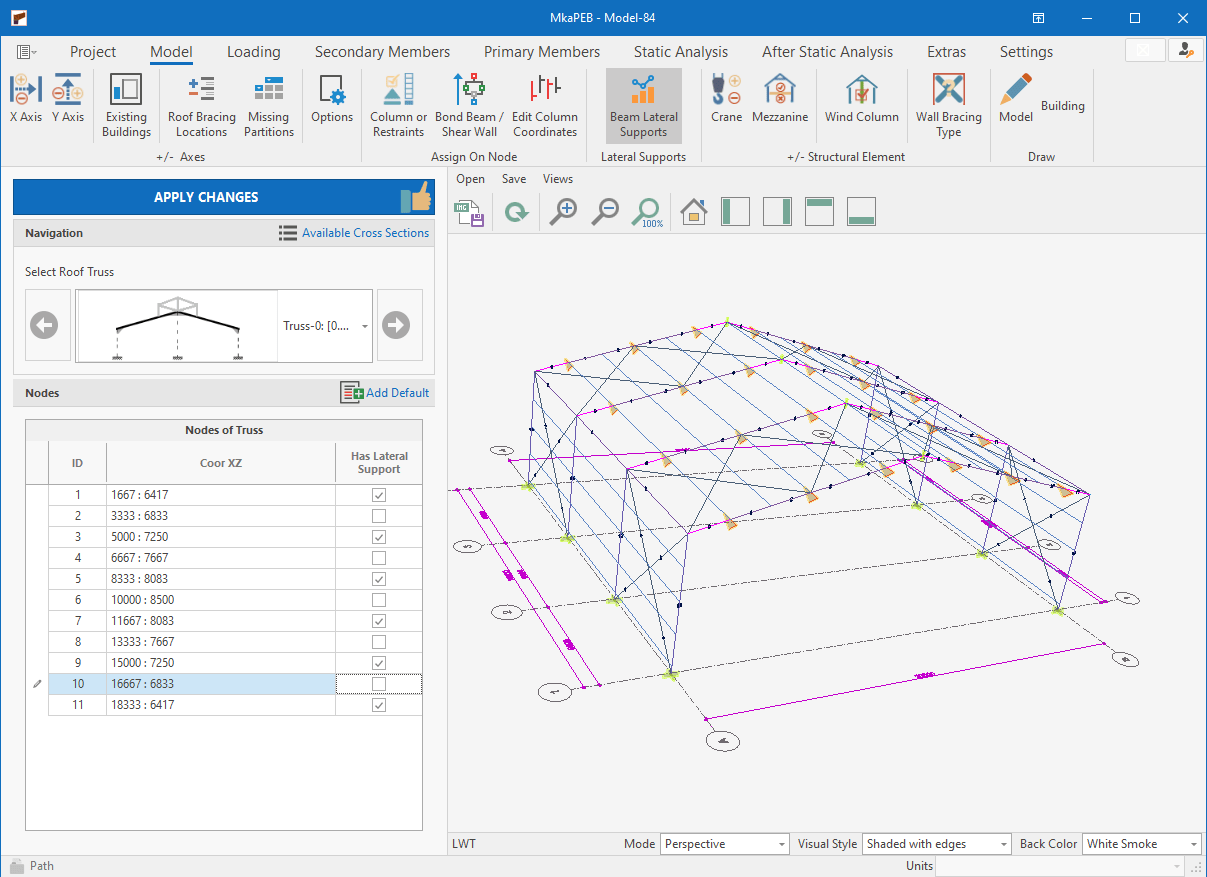

Lateral support elements are used in three places in MkaPEB.

- To prevent lateral torsional buckling in beams,

- To prevent lateral torsional buckling in columns,

- To reduce the buckling length of the lower header in steel shears

- To reduce the lateral displacement of the crane runway beam

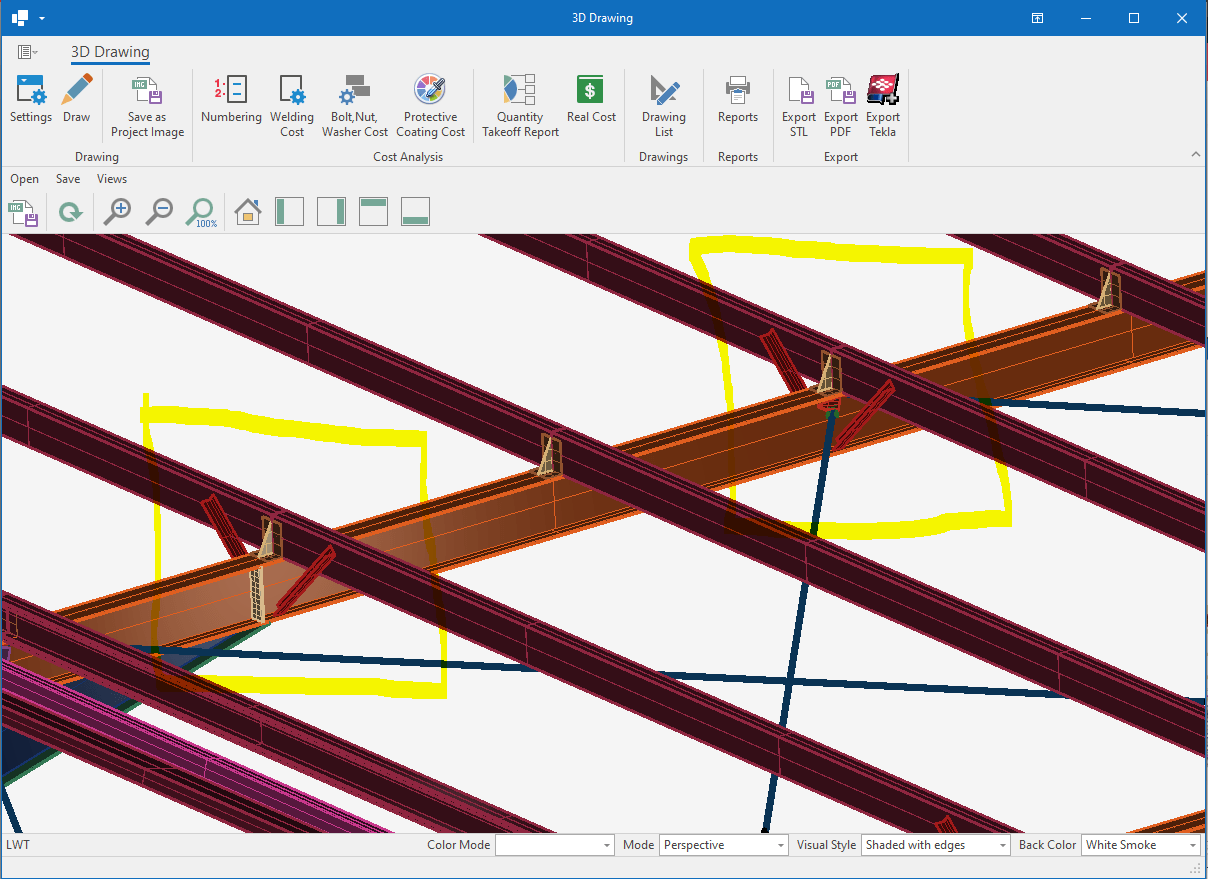

1- Beam flange (fly) bracing- To prevent lateral torsional buckling

2- Column flange (fly) bracing - To prevent lateral torsional buckling

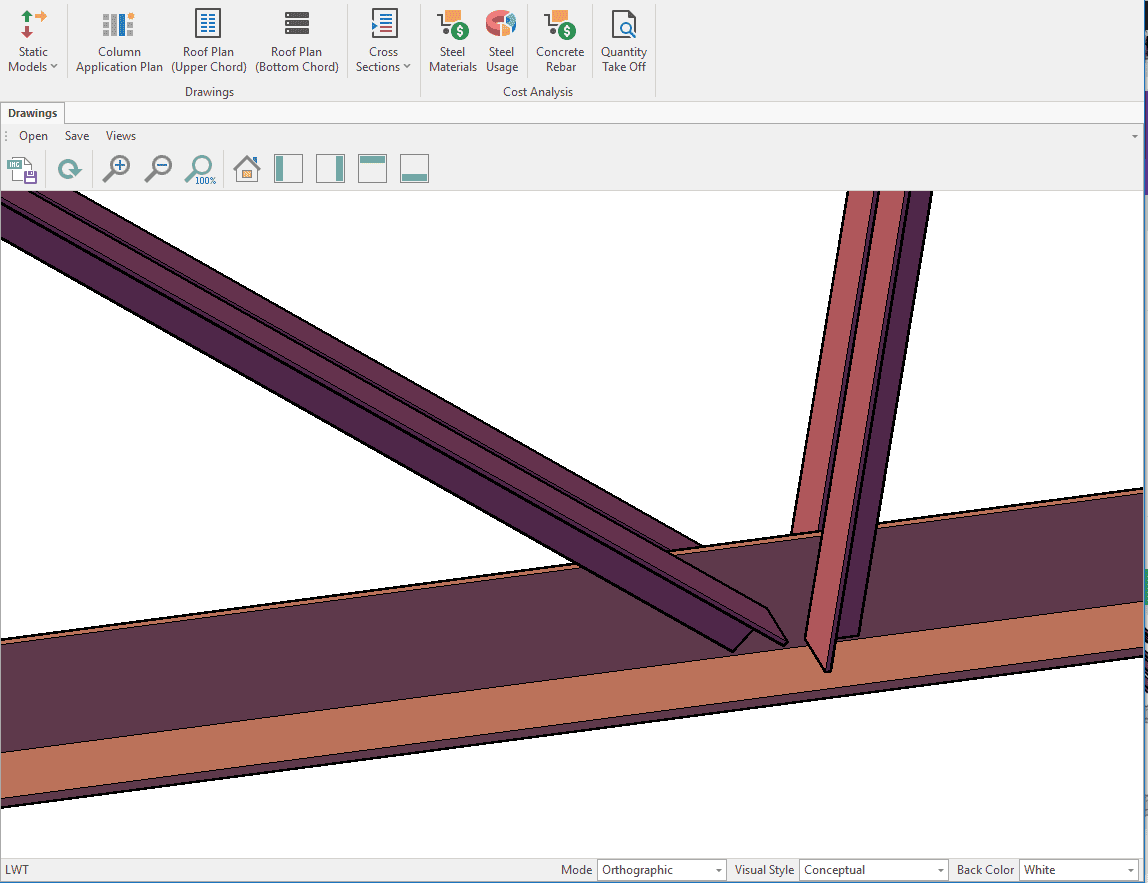

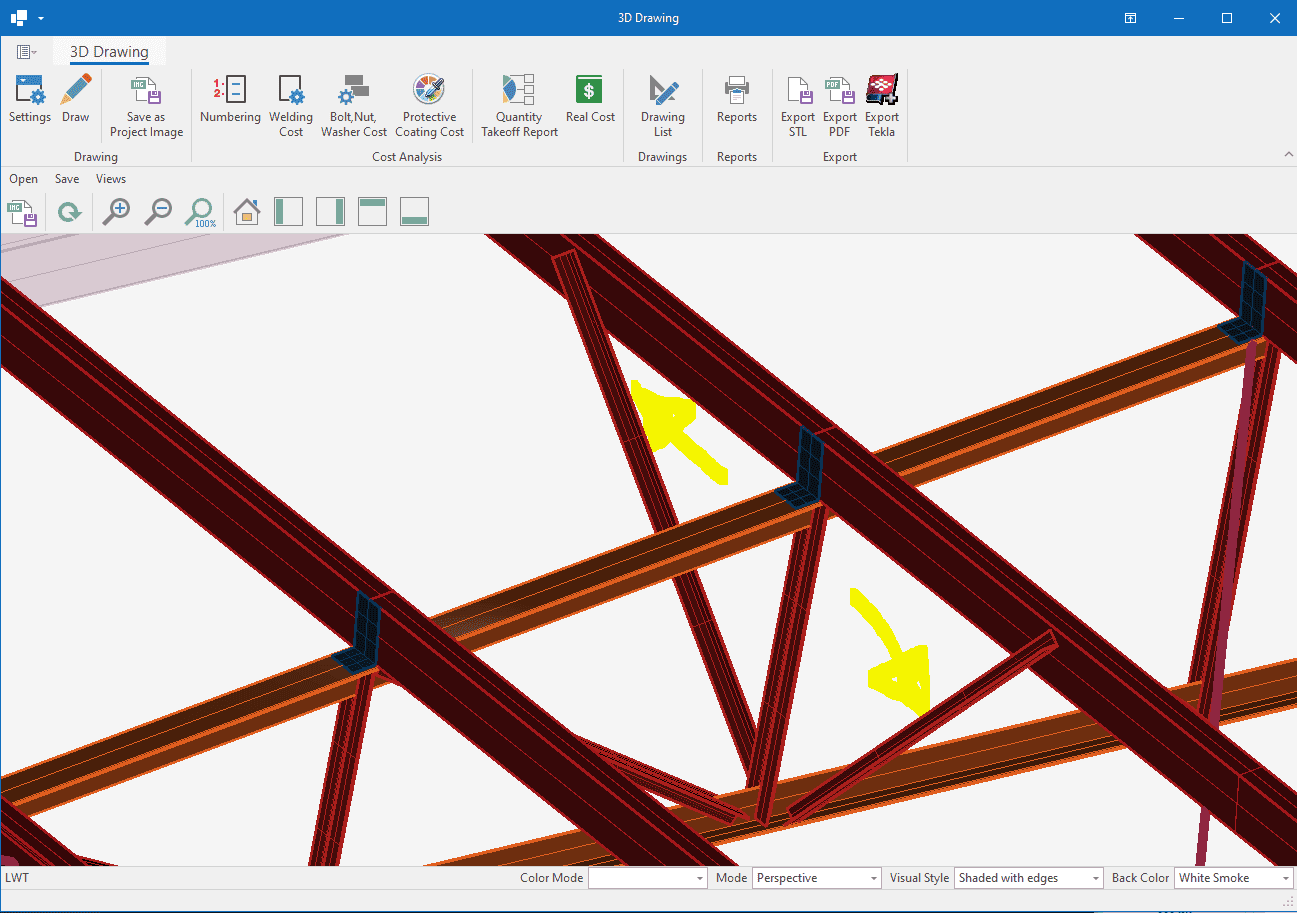

3- Truss lowerchord bracing - To prevent buckling about minor axis

PEB Rafter web thickness

This is a great solution for anyone looking to overcome the challenges of cross bracing and ensure smooth and efficient movement for both men and machines. Portal bracing is a fantastic secondary rigid frame that provides additional support between two primary rigid frames in a bay. It's a great alternative to a rigid frame with two columns and a rafter.

Truss chord additional plate

This is a great solution for anyone looking to overcome the challenges of cross bracing and ensure smooth and efficient movement for both men and machines. Portal bracing is a fantastic secondary rigid frame that provides additional support between two primary rigid frames in a bay. It's a great alternative to a rigid frame with two columns and a rafter.